How Rapid Prototypes Are Transforming Product Development in 2025

2025-11-12

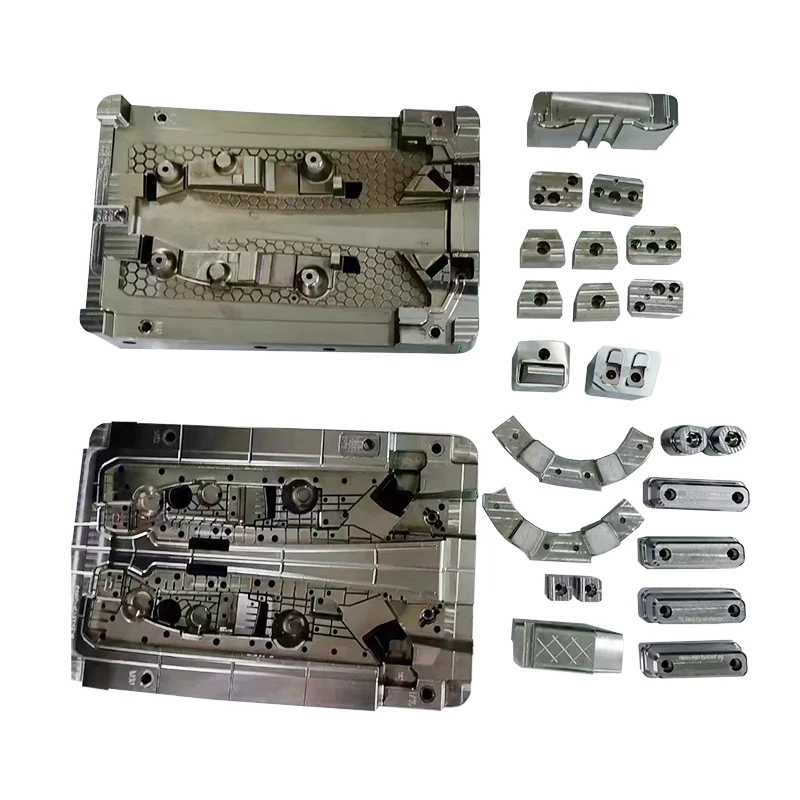

When I first joined Moldburger, I never imagined how quickly Rapid Prototypes would reshape the entire product development landscape. Over the past few years, we’ve watched this technology evolve from a simple testing method into a game-changing tool that helps manufacturers, designers, and engineers accelerate innovation, reduce costs, and improve precision. In 2025, the role of rapid prototyping has expanded beyond just speed—it’s now a strategic advantage for companies that want to stay ahead in competitive markets.

Why Are Rapid Prototypes So Essential for Modern Product Development?

The biggest challenge we often hear from our clients is time. Traditional prototyping methods take weeks or even months. In contrast, rapid prototyping allows us to design, test, and modify parts in just days—sometimes even hours.

Here’s how this shift impacts the entire process:

-

Faster Design Validation: Engineers can instantly visualize and test their ideas.

-

Lower Development Costs: Iterations are cheaper, reducing waste from tooling and materials.

-

Improved Collaboration: Digital models and physical samples make communication across teams more effective.

-

Market Agility: Products reach the market faster, giving clients a strong competitive edge.

What Are the Key Features of Our Rapid Prototyping Solutions?

At Moldburger, we’ve spent years refining our prototyping process to meet the highest industrial standards. Our equipment and materials support a wide range of applications, from automotive to consumer electronics.

| Feature | Specification | Benefit |

|---|---|---|

| Material Range | ABS, Nylon, Resin, Aluminum, Stainless Steel | Ideal for both functional and visual prototypes |

| Printing Technology | SLA, SLS, FDM, CNC Machining | Flexible solutions for complex geometries |

| Tolerance Accuracy | ±0.02 mm | High-precision output for engineering verification |

| Lead Time | 1–3 days | Rapid turnaround for urgent development needs |

| Surface Finish Options | Polishing, Sandblasting, Painting, Anodizing | Ready-for-presentation product finish |

| File Compatibility | STEP, STL, IGES, CAD | Easy integration with client design software |

These technical details might look simple on paper, but they’re what make our prototypes reliable and production-ready.

How Does Rapid Prototyping Solve Real-World Product Challenges?

In my daily work, I see many clients struggle with balancing speed, cost, and accuracy. Rapid prototyping bridges that gap perfectly. By combining digital manufacturing and physical validation, companies can:

-

Detect design flaws early before mass production.

-

Reduce tooling investments by testing with prototypes first.

-

Accelerate investor approval with tangible models.

-

Enhance customization without long manufacturing delays.

One of our recent clients in the automotive industry reduced their prototype cycle from three weeks to four days—cutting costs by nearly 60%. That’s the kind of measurable difference that keeps our partners returning.

What Makes Moldburger Different from Other Rapid Prototyping Suppliers?

I often tell our customers that our advantage isn’t just the machinery—it’s our experience and precision-driven mindset. With advanced production lines, strict quality inspection, and a dedicated R&D team, we handle every stage in-house.

Our process includes:

-

Real-time project tracking for transparency.

-

Professional engineering advice to refine designs.

-

Flexible volume production once prototypes are approved.

This full-service approach ensures each prototype aligns with the customer’s functional and aesthetic goals.

How Can You Start Your Rapid Prototyping Project with Us?

If you’re ready to see how Rapid Prototypes can transform your next product, we’d love to help. Whether you need one part or a full assembly, our team at Moldburger is ready to turn your concept into reality.

Reach out today to discuss your design, material, and timeline needs. Simply contact us through our website or send us your CAD files for a free quotation. Let’s build something extraordinary—fast.