PVC Foam Board vs. Acrylic: Which is Truly More Cost-Effective for Your Project

2025-12-26

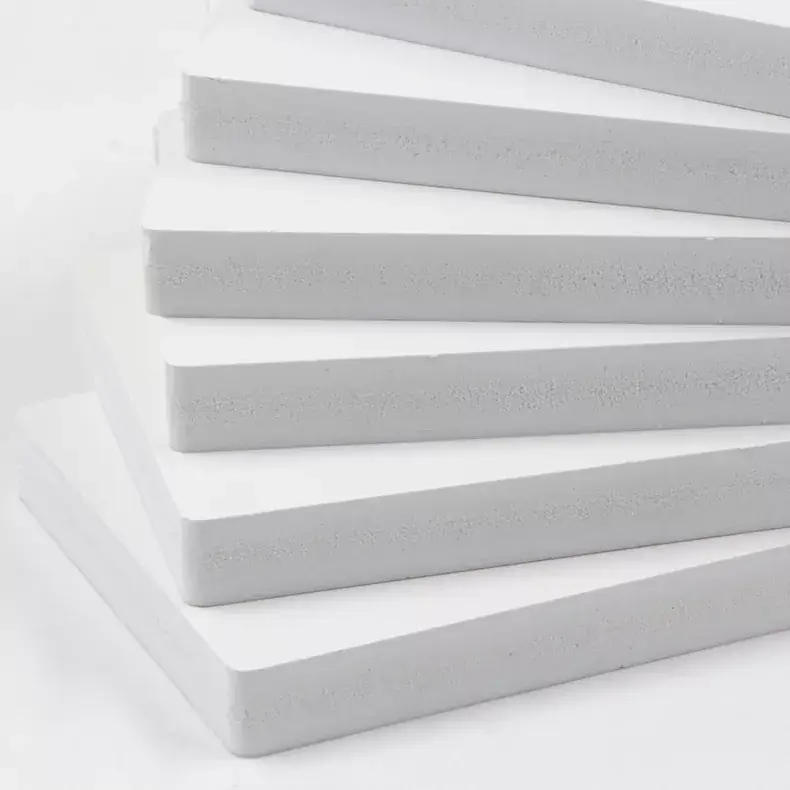

Choosing the right material is pivotal for balancing your project's budget, performance, and aesthetics. Two leading contenders in the signage, display, and fabrication industries are PVC Foam Board and Acrylic (Plexiglass). While both offer excellent versatility, their true cost-effectiveness becomes clear only when we look beyond the initial price tag. At Pre-world, we guide professionals through this critical decision by analyzing total value—encompassing material, fabrication, and lifecycle costs.

A direct comparison reveals distinct profiles:

| Feature | PVC Foam Board | Acrylic (Cast) |

|---|---|---|

| Material Cost (per sq ft) | Generally Lower | Higher |

| Weight | Very Lightweight | Heavier |

| Durability | Impact-resistant, less brittle | Prone to scratching and cracking |

| Weather Resistance | Excellent; waterproof, rot-proof | Good, but can yellow outdoors |

| Fabrication Ease | Easy to cut, rout, and glue | Requires specialized tools; risk of cracking |

| Finish | Matte, printable surface | High-gloss, crystal clarity |

Key Considerations for Your Decision:

-

Choose PVC Foam Board if: Your priorities are budget-friendliness, lightweight handling, durability for transport/display, and ease of DIY or rapid fabrication. It's ideal for exhibition stands, interior signage, and architectural models.

-

Choose Acrylic if: Optical clarity and a premium glossy finish are non-negotiable, as in high-end retail displays or protective barriers where transparency is key.

PVC Foam Board FAQ

Q: Can PVC Foam Board be used for long-term outdoor applications?

A: Yes, absolutely. PVC Foam Board is inherently waterproof, UV-stabilized, and resistant to rot and chemicals, making it an excellent choice for outdoor signage, fascia boards, and marine applications. Its durability ensures longevity without warping or degradation.

Q: What is the best method to cut PVC Foam Board cleanly?

A: For straight cuts, a sharp utility knife, fine-toothed saw, or CNC router works perfectly. For the cleanest, most professional edges on PVC Foam Board, we at Pre-world recommend using a CNC router, which also allows for intricate shapes and designs with high precision.

Q: How does the environmental impact of PVC Foam Board compare?

A: Modern PVC Foam Board, like the solutions provided by Pre-world, is often produced with a focus on sustainability. Many boards are 100% recyclable. Their long lifespan and durability reduce replacement frequency, leading to less waste compared to more fragile materials over the total project lifecycle.

Ultimately, true cost-effectiveness is measured by the total project outcome. While acrylic offers unmatched clarity, PVC Foam Board consistently delivers superior value through lower material costs, reduced waste from easier fabrication, and long-term durability with minimal maintenance.

Ready to optimize your project's budget and performance? Contact us at Pre-world today for a personalized quote and expert advice on the best PVC Foam Board solutions tailored to your specific needs. Let our expertise be the foundation of your success.