What Are The Common Thicknesses of Color Steel Plates?

2025-12-25

In the construction and light steel building industry, thickness selection is one of the first technical decisions engineers and buyers must make. The thickness of a Color Steel Plate directly affects load capacity, service life, thermal behavior, and installation efficiency. Based on long-term project experience in industrial plants, warehouses, and prefabricated structures, our factory has found that most users focus not only on nominal thickness values but also on coating weight, substrate grade, and application environment. At Suzhou Wanyu Steel Structure Building Installation Engineering Co., Ltd., we work closely with contractors and designers to match thickness specifications with real structural and climatic requirements.

Why Does Thickness Matter in Practical Construction Applications?

Thickness determines how a Color Steel Plate performs under wind load, snow pressure, and daily thermal expansion. In regions with strong winds or heavy seasonal snowfall, thicker plates provide higher rigidity and reduce the risk of deformation. Our engineering team often explains to clients that thickness is not simply about strength, but about long-term stability and maintenance cost control. In our factory, thickness selection is always evaluated together with span length, purlin spacing, and fastening methods.

At Suzhou Wanyu Steel Structure Building Installation Engineering Co., Ltd., we regularly supply projects where improper thickness selection in earlier designs led to vibration noise or premature surface fatigue. By aligning plate thickness with structural calculations, our technical staff helps reduce these risks and improve overall building performance.

What Are the Most Common Thickness Ranges Used in the Market?

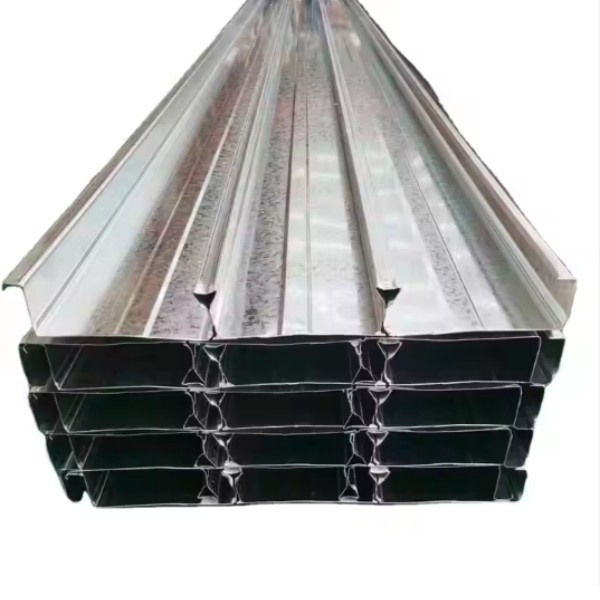

Across industrial and commercial construction, most Color Steel Plate products fall within a clearly defined thickness range. Thin plates are widely used for wall cladding, while thicker plates are selected for roofing systems and load-bearing components. Our factory typically manufactures plates within standardized tolerances to meet both local building codes and international project specifications.

The table below outlines commonly used thickness ranges and their typical applications in real projects.

| Thickness Range | Common Application | Structural Role | Notes from Field Use |

| 0.3 mm to 0.4 mm | Interior walls and partitions | Non load bearing | Lightweight and cost efficient |

| 0.4 mm to 0.5 mm | External wall cladding | Envelope protection | Good balance of strength and weight |

| 0.5 mm to 0.6 mm | Industrial roofing systems | Weather resistance | Common choice for factories and warehouses |

| 0.6 mm to 0.8 mm | Heavy duty roofing | High load resistance | Used in high wind or snow load zones |

How Do Substrate and Coating Affect Effective Thickness?

When discussing thickness, many buyers overlook the difference between base steel thickness and total coated thickness. The zinc layer and color coating add protective value but do not significantly increase structural strength. In our factory, we clearly separate substrate thickness from coating weight during production and inspection. This ensures transparency and helps buyers make informed decisions when comparing suppliers.

Suzhou Wanyu Steel Structure Building Installation Engineering Co., Ltd. emphasizes stable coating adhesion and uniform thickness control, especially for projects exposed to moisture or industrial atmospheres. By managing these factors together, our engineers ensure the Color Steel Plate maintains both appearance and corrosion resistance throughout its service life.

Which Thickness Is Suitable for Roofing Versus Wall Systems?

Roofing systems typically require thicker plates due to direct exposure to wind uplift, rain impact, and temperature fluctuation. Wall systems, on the other hand, prioritize insulation compatibility and ease of installation. Our factory commonly recommends thickness above 0.45 mm for roofing applications, while wall panels can function effectively at slightly lower ranges depending on support spacing.

The table below compares typical thickness selections for roofing and wall systems used in industrial buildings.

| Application Area | Recommended Thickness | Performance Focus | Engineering Consideration |

| Roof panels | 0.45 mm to 0.6 mm | Load resistance and sealing | Span length and fastening design |

| Wall panels | 0.35 mm to 0.5 mm | Appearance and insulation | Wind pressure and panel width |

How Do Climate and Regional Standards Influence Thickness Selection?

Local climate conditions play a critical role in thickness decisions. Coastal regions require stronger corrosion resistance, while inland cold regions demand better structural stability against snow accumulation. Our factory frequently adjusts thickness recommendations based on regional wind maps and snow load data. These considerations are especially important for export projects where local standards may differ.

At Suzhou Wanyu Steel Structure Building Installation Engineering Co., Ltd., our technical consultations often include a review of regional building codes to ensure the selected Color Steel Plate thickness aligns with compliance requirements and long-term safety expectations.

What Are The Common Thicknesses of Color Steel Plates? FAQ

Q1: What thickness is most commonly used for industrial warehouse roofing?

For industrial warehouse roofs, thickness between 0.45 mm and 0.6 mm is most commonly used. This range offers sufficient strength to handle wind uplift and maintenance loads while maintaining reasonable material cost.

Q2: Can thinner plates be used if purlin spacing is reduced?

Yes, reducing purlin spacing can allow the use of thinner plates in certain applications. However, this approach may increase overall structural cost and installation time, so a balanced evaluation is recommended.

Q3: Does thicker always mean better performance?

Not necessarily. Excessive thickness may increase weight and cost without providing proportional benefits. Proper thickness selection should be based on load calculations, environment, and intended service life.

Conclusion

Understanding the common thicknesses of Color Steel Plate is essential for achieving reliable structural performance and cost efficiency. Thickness selection should always consider application type, climate conditions, substrate quality, and installation design. Our factory combines production control with practical engineering experience to support a wide range of construction needs. At Suzhou Wanyu Steel Structure Building Installation Engineering Co., Ltd., we provide technical guidance and customized solutions to help clients select the most suitable specifications. Contact our team today to discuss your project requirements and receive professional support for your next steel structure application.