What Makes Durable Lightweight Structural Components the Right Choice

2025-09-19

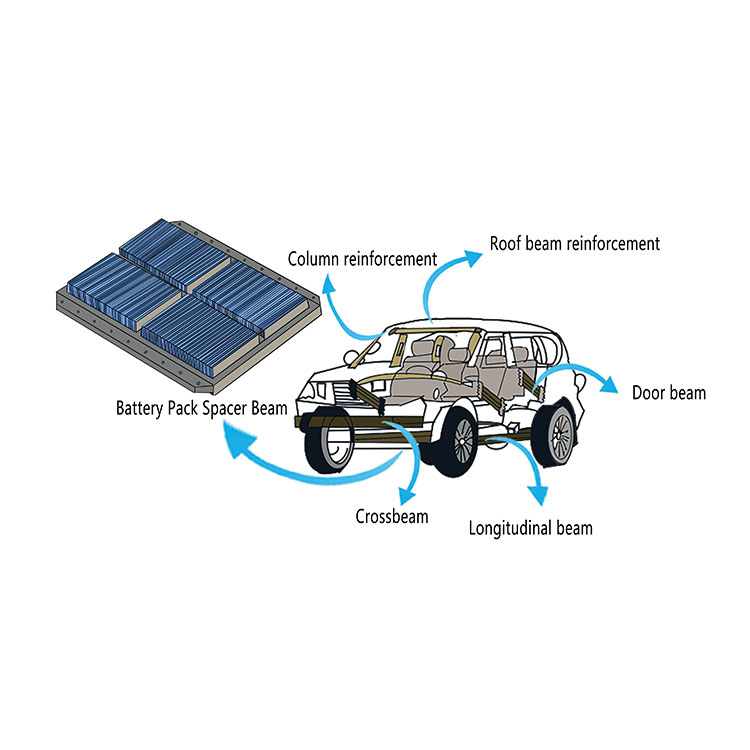

When I introduce our SPARE products to clients, I often highlight how our Vehicle Composite Profiles solve some of the biggest challenges in modern engineering. Many industries today demand components that are not only strong but also lightweight and adaptable. Over the years, we have refined our materials and processes to provide solutions that combine durability, weight reduction, and cost efficiency.

Why Should You Consider Lightweight Structural Components

In transportation, construction, and industrial design, every gram matters. Reducing weight can increase efficiency, lower fuel consumption, and improve safety. Our components are engineered with advanced composites that deliver these advantages without sacrificing strength.

What Are the Key Parameters of Our Products

To give you a clearer picture, here are the main parameters we provide for our structural components:

-

High strength-to-weight ratio for optimal performance

-

Excellent resistance to corrosion and chemicals

-

Thermal stability across extreme temperatures

-

Customizable profiles to meet industry-specific needs

-

Long service life with minimal maintenance requirements

Typical Technical Specifications

| Parameter | Value Range | Benefit to Clients |

|---|---|---|

| Density | 1.6 – 2.0 g/cm³ | Lightweight for energy efficiency |

| Tensile Strength | 300 – 600 MPa | High load-bearing capability |

| Flexural Modulus | 20 – 40 GPa | Enhanced stiffness and stability |

| Operating Temperature | -40°C to +120°C | Reliable in diverse environments |

| Corrosion Resistance | Excellent | Long service life in harsh conditions |

How Do These Components Improve Performance

By integrating our lightweight structural components into vehicles, clients have reported improved fuel economy and reduced emissions. In construction, these profiles make assembly easier, cutting down on labor and installation time. For industrial machinery, the components provide reliability under stress, reducing the need for frequent replacements.

Why Work With Our Team

From the very beginning, our focus has been on practical solutions. I work closely with engineers and project managers to ensure each component is tailored to specific requirements. Unlike off-the-shelf products, our profiles can be adjusted in terms of shape, strength, and finish, giving clients flexibility in their designs.

How Can You Get Started

If you are exploring ways to enhance your projects with durable and lightweight solutions, I encourage you to get in touch with us today. Our team is ready to discuss your needs, share case studies, and provide technical guidance. Please contact us to request more details or leave an inquiry—we look forward to supporting your next project with precision-engineered components.