Why Are Conveyor Components Crucial for Modern Material Handling?

2025-09-15

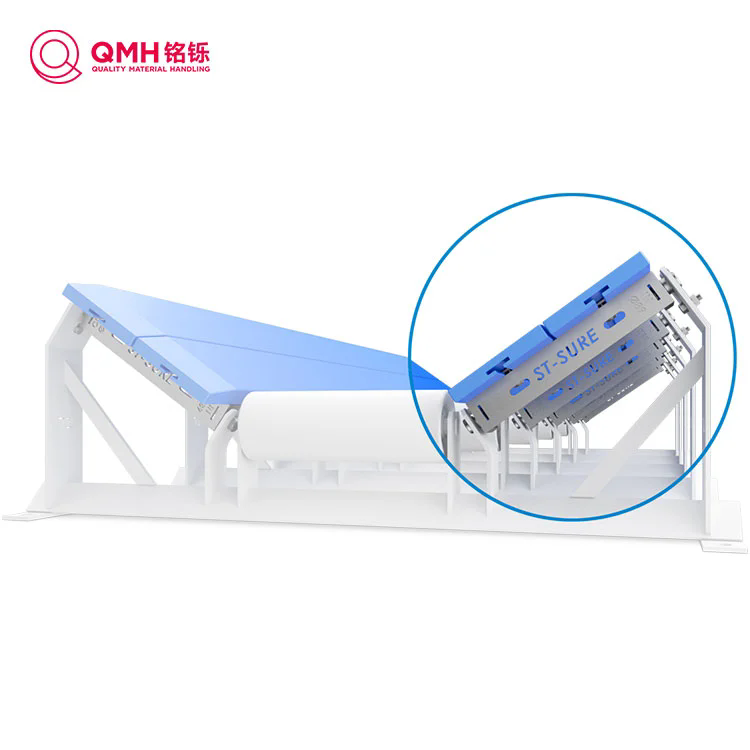

In every industry where bulk goods, packages, or raw materials must be moved efficiently, conveyor systems are at the heart of operations. From mining and steel production to food processing and e-commerce fulfillment centers, conveyors eliminate the inefficiencies of manual handling. Yet, a conveyor system is only as reliable as its components. Conveyor components—including rollers, pulleys, belts, idlers, frames, bearings, cleaners, and safety devices—determine how smoothly, safely, and economically a system performs.

To understand the importance of these elements, it is worth noting that conveyors are not single machines but engineered systems composed of interdependent parts. A single malfunctioning roller, for instance, can trigger belt misalignment, excessive wear, or even complete shutdown. Likewise, poorly designed pulleys can reduce power transmission efficiency, while inadequate belt cleaners can lead to spillage and downtime.

Industries that rely heavily on conveyor technology are constantly seeking improvements in efficiency, durability, and safety. This demand drives innovation in conveyor component design—leading to lighter yet stronger rollers, energy-efficient drives, advanced materials for belts, and automated monitoring systems that detect wear before breakdowns occur.

What Defines High-Quality Conveyor Components?

High-quality components share three defining characteristics:

-

Durability – Built to withstand abrasive materials, high loads, and demanding environments.

-

Precision Engineering – Designed to reduce friction, minimize energy consumption, and ensure consistent alignment.

-

Compatibility – Engineered to integrate seamlessly with various conveyor systems without compromising efficiency.

A reliable supplier must not only offer components that meet these requirements but also provide technical support and customization options for unique operational needs.

Technical Specifications and Key Conveyor Component Types

To provide a clear professional perspective, let’s examine the main conveyor components with their typical parameters. These specifications often serve as benchmarks when selecting components for specific industries:

| Component Type | Standard Materials | Typical Specifications | Key Functions |

|---|---|---|---|

| Rollers & Idlers | Steel, HDPE, Rubber-Coated | Diameter: 50–159 mm; Load capacity: 50–600 kg per roller | Support the belt, reduce friction, ensure smooth transport |

| Conveyor Belts | Rubber, PVC, PU, Modular Plastic | Width: 300–2000 mm; Thickness: 3–20 mm; Tensile strength: 800–3150 N/mm | Carry materials efficiently, withstand heavy loads, resist wear |

| Pulleys | Mild Steel, Stainless Steel, Lagging (Ceramic/Rubber) | Diameters: 200–1200 mm; Shaft length per design | Transmit power, maintain belt tension, aid in belt tracking |

| Bearings & Housings | Chrome Steel, Stainless Steel | Sealed or open type; Bore sizes: 20–120 mm | Reduce friction, extend component life, ensure smooth rotation |

| Belt Cleaners | Polyurethane, Tungsten, Carbide Blades | Primary, secondary, or specialty designs | Remove material carryback, reduce spillage, minimize wear |

| Safety Devices | Emergency Stop Pull Cords, Belt Misalignment Switches | IP65/67 protection; operating range 10–30 m | Protect workers, prevent accidents, reduce downtime |

These components are not standalone products—they form the backbone of an integrated material handling system. Engineers and operators select combinations based on throughput requirements, environmental conditions, and safety regulations.

Why Precise Specifications Matter

Precise specifications directly influence operational efficiency. For example, selecting the wrong roller diameter can create excess drag on the belt, increasing energy costs. Similarly, using belts with insufficient tensile strength can result in premature failure under heavy loads. By aligning specifications with operational requirements, businesses optimize performance, reduce downtime, and extend the life of their equipment.

The Benefits of Using Advanced Conveyor Components

The choice of conveyor components has far-reaching implications for productivity and cost management. Companies that invest in high-grade parts experience measurable benefits in their operations.

Enhanced Efficiency

Energy-efficient rollers, low-resistance bearings, and precision pulleys minimize power consumption. Over time, these efficiencies reduce electricity bills and contribute to sustainable operations. In industries handling thousands of tons daily, even marginal energy savings translate into significant cost reductions.

Improved Safety

Modern conveyor systems are equipped with safety-focused components such as emergency stop pull cords, misalignment sensors, and advanced guarding systems. These elements ensure compliance with occupational safety regulations while protecting workers from hazards associated with high-speed machinery.

Reduced Maintenance

Premium-quality components are engineered for longevity. Anti-corrosive coatings, self-lubricating bearings, and wear-resistant belts lower maintenance frequency and costs. For industries operating around the clock, minimizing downtime is critical, and durable components provide a significant advantage.

Customization and Adaptability

Not every conveyor system operates under the same conditions. Mining conveyors require heavy-duty belts capable of withstanding abrasive ores, while food-grade conveyors demand hygienic, FDA-compliant materials. Modern manufacturers now provide customizable options, ensuring that conveyor components are tailored to industry-specific requirements.

Common Questions About Conveyor Components

In material handling, decision-makers often have recurring questions about conveyor components. Addressing these concerns provides clarity for buyers and engineers alike.

Q1: What factors should I consider when selecting conveyor rollers?

When selecting rollers, focus on load capacity, material, diameter, and environmental conditions. For example, steel rollers are ideal for heavy loads, while HDPE rollers perform well in corrosive environments. Noise reduction may also be important in logistics centers or warehouses. Always ensure compatibility with belt type and operating speed.

Q2: How can I extend the lifespan of my conveyor components?

The lifespan of conveyor components can be extended through regular inspection, proper lubrication of bearings, timely replacement of worn parts, and the use of belt cleaners to prevent material buildup. Additionally, selecting high-quality components from the beginning reduces wear and helps maintain system efficiency over time.

Building Reliable Systems with Conveyor Components

The success of a conveyor system lies in the quality and precision of its components. Whether it’s the rollers that provide belt support, the pulleys that drive motion, or the safety devices that protect workers, each part plays an indispensable role in achieving smooth material flow. As industries face growing demands for speed, efficiency, and safety, the emphasis on selecting advanced conveyor components continues to rise.

For companies seeking long-term reliability and efficiency, partnering with trusted providers is essential. qmh stands out as a brand dedicated to delivering durable, high-performance conveyor components that meet the diverse needs of industries worldwide. By choosing the right parts and supplier, businesses not only enhance productivity but also secure the long-term success of their operations.

If you are looking to upgrade or maintain your conveyor systems with premium components, contact us today to learn more about tailored solutions for your industry.