Why Are Energy Storage Thermal Management Tubes Essential for Modern Energy Systems?

2025-09-09

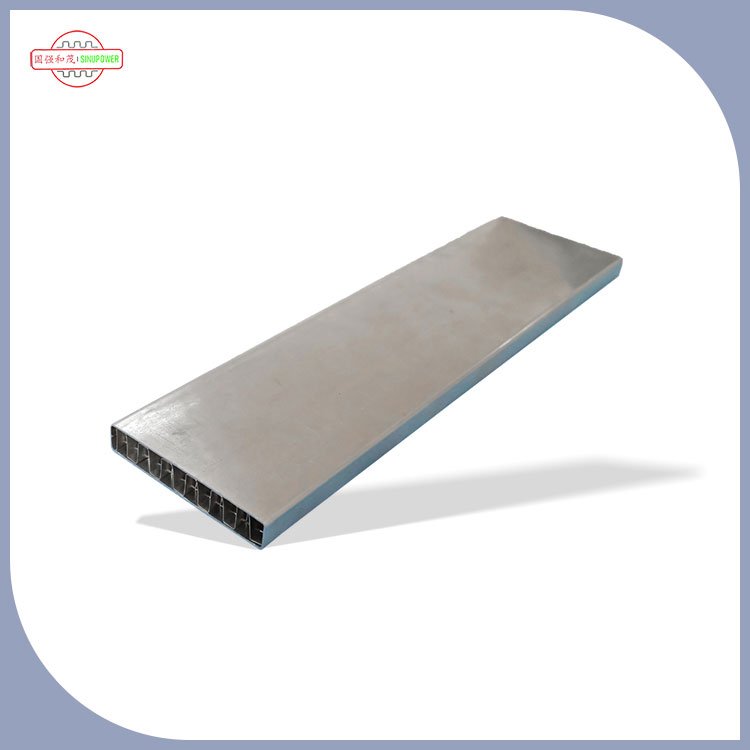

As global energy systems transition towards higher efficiency and greater sustainability, the importance of effective heat transfer and storage solutions has grown exponentially. Among the critical components driving this progress are Energy Storage Thermal Management Tubes. These tubes are designed to optimize thermal regulation in energy storage units, ensuring stable performance, extended lifespan, and safe operation.

At Sinupower Heat Transfer Tubes Changshu Ltd., we specialize in manufacturing advanced thermal management solutions tailored for modern energy applications. Our Energy Storage Thermal Management Tubes are engineered with precision, offering a balance of high durability, corrosion resistance, and superior thermal conductivity.

What Are Energy Storage Thermal Management Tubes?

Energy Storage Thermal Management Tubes are engineered conduits used in energy storage systems—particularly in battery energy storage systems (BESS), concentrated solar power storage, and advanced thermal energy storage units. They enable efficient thermal exchange, ensuring that stored energy is maintained at safe and optimal operating temperatures.

These tubes are designed to withstand extreme temperature variations, provide reliable mechanical strength, and minimize energy losses due to heat imbalance. In practical terms, this means lower system failure risks, higher performance efficiency, and enhanced safety.

Key Functions and Advantages

-

Temperature Regulation: Prevents overheating or excessive cooling in storage systems.

-

Safety Enhancement: Reduces fire hazards by stabilizing internal thermal conditions.

-

Performance Optimization: Improves charge-discharge efficiency in battery energy storage systems.

-

Longevity: Extends the operational lifespan of energy storage devices.

-

Scalability: Suitable for both small-scale storage and large industrial installations.

Product Specifications

At Sinupower Heat Transfer Tubes Changshu Ltd., our Energy Storage Thermal Management Tubes are available in multiple configurations to suit different applications. Below is a summary of key product parameters:

| Parameter | Specification Range |

|---|---|

| Material | Copper, Stainless Steel, Aluminum Alloy |

| Outer Diameter (OD) | 6 mm – 40 mm |

| Wall Thickness | 0.4 mm – 2.5 mm |

| Thermal Conductivity | Up to 390 W/m·K (material-dependent) |

| Working Temperature | -40°C to +350°C |

| Pressure Resistance | Up to 10 MPa |

| Surface Treatment Options | Smooth, Grooved, Inner-Rifled |

| Application Fields | Battery Packs, Solar Storage, EV Charging Units, Grid-Level Storage |

Application Areas

-

Battery Energy Storage Systems (BESS): Maintaining stable battery temperatures improves charging efficiency and prevents thermal runaway.

-

Renewable Energy Storage: Ideal for solar thermal storage and wind energy storage systems where temperature fluctuations are significant.

-

Electric Vehicles (EV): Used in thermal management of EV battery packs to enhance driving range and safety.

-

Industrial Energy Management: Supports large-scale storage units in factories, data centers, and grid balancing projects.

Why Choose Sinupower Heat Transfer Tubes Changshu Ltd.?

-

Industry Expertise: Over two decades of engineering and manufacturing excellence.

-

Advanced Manufacturing: Precision tube drawing, grooving, and surface treatments with strict quality control.

-

Custom Solutions: Flexible designs to meet specific customer needs.

-

Global Supply Capability: Products exported worldwide with proven reliability in diverse applications.

Frequently Asked Questions

Q1: What makes Energy Storage Thermal Management Tubes different from standard heat transfer tubes?

A1: Unlike conventional tubes, Energy Storage Thermal Management Tubes are optimized for energy storage environments where consistent and controlled thermal performance is vital. They are designed to withstand high cycling rates, maintain efficiency under variable loads, and resist thermal fatigue.

Q2: How do Energy Storage Thermal Management Tubes improve the safety of battery systems?

A2: By ensuring uniform temperature distribution, these tubes prevent localized hotspots that may trigger thermal runaway. This thermal balance significantly lowers fire risks and ensures safe operation even in high-capacity battery packs.

Q3: Can Energy Storage Thermal Management Tubes be customized for specific energy storage projects?

A3: Yes. At Sinupower Heat Transfer Tubes Changshu Ltd., we offer fully customizable options including material selection, diameter, wall thickness, and internal grooving. This allows customers to optimize tubes according to their project's thermal management requirements.

Q4: What maintenance is required for Energy Storage Thermal Management Tubes?

A4: Maintenance is minimal. Regular inspection of fluid quality and pressure levels is generally sufficient. The robust material construction and corrosion resistance reduce the need for frequent replacement or repairs, ensuring cost-effective long-term use.

Conclusion

As renewable energy and advanced storage solutions continue to evolve, the demand for reliable thermal management technology will only grow stronger. Energy Storage Thermal Management Tubes play a pivotal role in ensuring system efficiency, safety, and durability.

At Sinupower Heat Transfer Tubes Changshu Ltd., we are committed to delivering high-performance solutions that empower the energy industry to meet future challenges. For more details, inquiries, or custom project requirements, please contact our technical team today.

👉 Contact Sinupower Heat Transfer Tubes Changshu Ltd. to learn more about our Energy Storage Thermal Management Tubes and how they can optimize your energy storage systems.