Why Are Flat Oval Tubes Becoming the Preferred Choice for High-Efficiency Engineering Applications?

2025-11-25

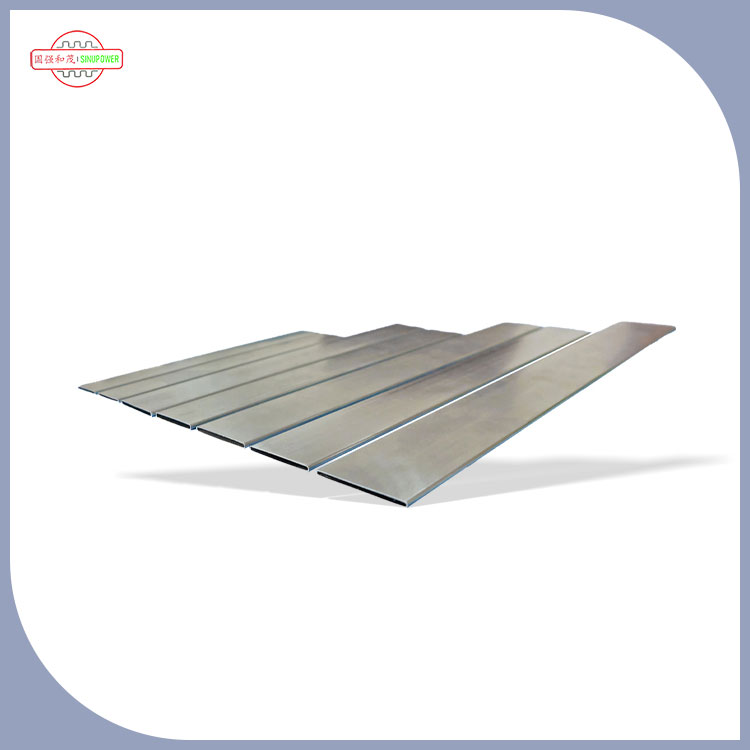

Flat Oval Tubes are engineered metal tubes with an elliptical-flattened profile designed to optimize airflow, heat transfer, structural stability, and space utilization across industrial, architectural, and automotive applications. Their specialized geometry reduces resistance, enhances strength-to-weight ratio, and allows systems to fit into compact layouts where traditional round tubes are limited.

To support professional engineering selection and procurement, detailed parameters of our Flat Oval Tubes are summarized below.

Key Technical Specifications

| Parameter Category | Details |

|---|---|

| Material Options | Stainless Steel (304/316/321), Carbon Steel, Aluminum, Copper, Titanium |

| Tube Shape | Flat-Oval, Elliptical-Flattened, Semi-Oval |

| Outer Dimensions | Width: 20–150 mm; Height: 8–60 mm (customizable) |

| Wall Thickness | 0.5–5.0 mm depending on material and application load |

| Manufacturing Process | Cold Drawing / Welded Tube Forming / Annealed Finishing |

| Surface Finish | Pickled, Polished, Satin Finish, Sandblasted, Anti-Corrosion Coating |

| Tolerances | Precision ±0.05–±0.10 mm |

| Testing Standards | ASTM, EN, JIS, ISO 9001 Process Control |

| Applications | Heat Exchangers, HVAC, Automotive Exhaust Systems, Architectural Handrails, Aerospace Components |

What Are Flat Oval Tubes and Why Do Their Structural Properties Matter?

Flat Oval Tubes combine the aerodynamic benefits of an oval profile with the stability of a flattened cross-section. This shape significantly improves air passage efficiency and reduces pressure drop.

Why the Geometry Enhances Performance

-

Reduced Drag: The streamlined cross-section minimizes turbulence and pressure loss in HVAC and exhaust systems.

-

Improved Strength: Flattening creates a broader resistance surface, enhancing durability under load.

-

Optimized Space Utilization: Fits into compact mechanical spaces or architectural layouts more efficiently than round pipes.

-

Superior Heat Transfer: Increased surface area and controlled fluid dynamics boost heat-exchange efficiency.

Applications Where Shape Matters

Flat Oval Tubes are widely used in

-

high-efficiency heat exchangers,

-

evaporator coils,

-

structural railings requiring elegant aesthetics,

-

automotive exhaust and emissions systems,

-

aerospace fluid passages and lightweight frames.

The focus on geometry makes Flat Oval Tubes ideal for performance-driven industries where airflow, pressure management, and compact design are crucial.

Why Do Industries Prefer Flat Oval Tubes Over Round or Rectangular Tubes?

Reasons for Industrial Adoption

1. Enhanced Mechanical Efficiency

The wider flat face distributes stress evenly, offering higher tensile and bending strength compared to round tubes of similar weight. This is especially beneficial for:

-

bridge railings,

-

mechanical frames,

-

automotive chassis support structures.

2. Airflow and Fluid Dynamics Advantages

The flattened oval shape reduces resistance in ventilation systems and exhaust lines, improving energy efficiency and reducing operating costs.

3. Heat Transfer Optimization

Flat Oval Tubes expose more surface area while maintaining a controlled passage for fluids or gases, significantly improving heat exchange rates.

4. Lightweight Yet Strong

Engineers requiring weight-sensitive components—such as aerospace or high-speed automotive platforms—prefer Flat Oval Tubes due to their low mass without compromising structural integrity.

5. Superior Aesthetic Versatility

Architectural designers favor the smooth, modern profile for public structures, interior installations, and decorative elements.

How Are Flat Oval Tubes Manufactured and How Do These Processes Affect Performance?

1. Cold Drawing for Dimensional Precision

Cold drawing shapes the tube through a die, producing:

-

excellent dimensional accuracy,

-

smooth surface finishes,

-

increased material density for strength.

2. Welded and Formed Tubes for Cost Efficiency

High-frequency welded tubes are widely used for non-pressure applications or general structural use, offering cost-effective production at scale.

3. Heat Treatment and Annealing

Annealing enhances ductility, reduces brittleness, and ensures stability during bending or forming processes.

4. Surface Treatments

Optional finishes provide corrosion protection and aesthetic appeal. Examples include:

-

chemical pickling for oxide removal,

-

sandblasting for matte surfaces,

-

mirror polishing for architectural use.

5. Quality Assurance Standards

Flat Oval Tubes are tested through

-

hydraulic pressure tests,

-

eddy-current flaw detection,

-

dimensional tolerance measurement,

-

tensile and hardness testing.

These steps ensure the tubes perform reliably in critical engineering environments.

What Are the Future Trends Driving Flat Oval Tube Innovation?

1. Growth in High-Efficiency Energy Systems

With global demand for cleaner and more efficient systems, Flat Oval Tubes are increasingly integrated into:

-

advanced HVAC modules,

-

renewable-energy heat exchangers,

-

industrial condensers and boilers.

2. Automotive Lightweighting

Electric and hybrid vehicles require lightweight structures without sacrificing safety, making Flat Oval Tubes valuable for battery protection frames, cooling circuits, and airflow channels.

3. Architectural Customization and Smart Buildings

Modern architecture emphasizes sustainable, aesthetic, and modular design. Flat Oval Tubes align with:

-

green building frameworks,

-

minimalist design trends,

-

integrated decorative-structural elements.

4. High-Performance Metallurgy

Materials such as duplex stainless steel, titanium alloys, and ultra-thin aluminum sheets are being developed to further enhance:

-

corrosion resistance,

-

temperature tolerance,

-

thermal conductivity,

-

forming flexibility.

Common Questions About Flat Oval Tubes

Q1: What advantages do Flat Oval Tubes offer compared to round tubes in airflow systems?

A: Flat Oval Tubes reduce turbulence and maintain a more stable airflow path due to their streamlined shape. This leads to lower pressure drops, reduced energy consumption, and improved system efficiency. Their compact profile also fits easily into tight mechanical spaces where round pipes may not be suitable.

Q2: Can Flat Oval Tubes withstand high-pressure or high-temperature environments?

A: Yes, when manufactured with appropriate materials such as stainless steel 316 or titanium and processed through cold drawing and annealing, Flat Oval Tubes can endure high pressure, fluctuating temperatures, and corrosive environments. Their reinforced flat structure provides excellent resistance to bending and deformation.

Why Are Flat Oval Tubes a Smart Investment for Modern Engineering, and How Can Sinupower Support Your Projects?

Flat Oval Tubes combine structural stability, aerodynamic efficiency, and design versatility, making them essential for industries prioritizing performance, durability, and compact engineering. Their role in heat transfer, architecture, automotive systems, and advanced energy solutions continues to grow as technology evolves. As manufacturers develop stronger alloys and higher-precision forming techniques, the future promises even more efficient, lighter, and adaptable Flat Oval Tube solutions.

Sinupower provides high-grade Flat Oval Tubes crafted under strict quality standards to support demanding industrial, automotive, and architectural applications. With a focus on precision, stability, and customization, the brand offers reliable solutions for clients seeking long-term performance. For specifications, custom manufacturing, or engineering support, contact us to explore how Sinupower can enhance your next project.