Why Are Flat Oval Tubes Essential in Modern Heat Exchanger Applications?

2025-09-16

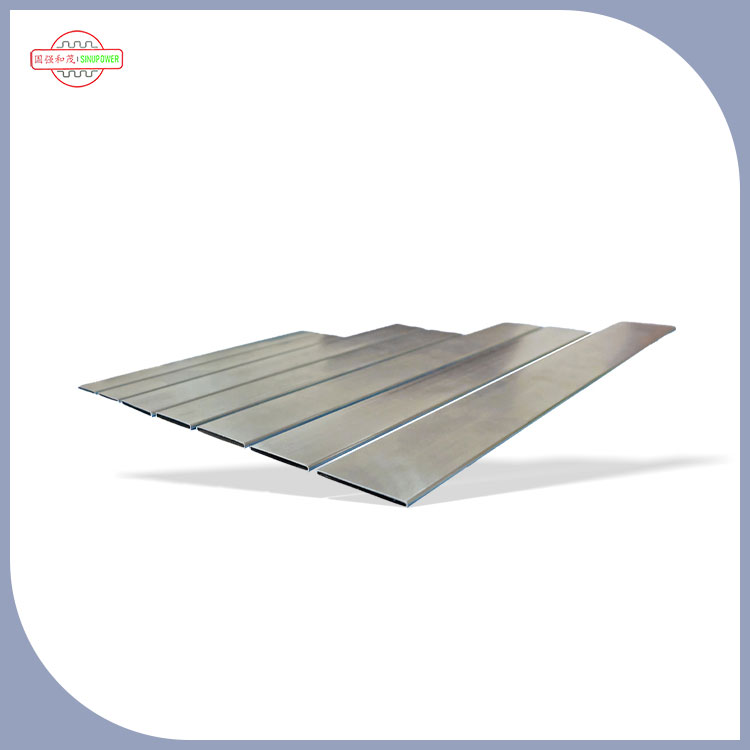

Flat Oval Tubes have become one of the most efficient and widely used components in the design of heat exchangers, condensers, and energy transfer equipment. Unlike traditional round tubes, their unique flattened oval profile enhances thermal performance while optimizing airflow and minimizing space requirements. From my professional experience, many clients often ask: Are Flat Oval Tubes really more efficient than round tubes? My answer is yes, and the following sections will clearly explain why.

What Are Flat Oval Tubes?

Flat Oval Tubes are specially designed tubes with an oval but flattened cross-section. They are manufactured to meet strict dimensional standards and are used in heat exchangers where higher efficiency and compact design are required. Compared to round tubes, they offer:

-

Increased heat transfer area within the same space

-

Reduced pressure drop across the tube bank

-

Enhanced structural strength

-

Better resistance to fouling

Main Functions of Flat Oval Tubes

The functions of Flat Oval Tubes can be summarized as follows:

-

Heat Transfer Enhancement – Providing higher efficiency by increasing the contact surface between the fluid and the tube wall.

-

Airflow Optimization – Their streamlined design reduces drag, improving the overall aerodynamic profile.

-

Space Efficiency – Ideal for compact systems where both size and performance matter.

-

Durability – Capable of withstanding thermal stress and mechanical load better than standard tubes.

Example Table

| Flat Oval Tubes | Round Tubes | |

|---|---|---|

| Heat Transfer Efficiency | Higher | Standard |

| Pressure Drop | Lower | Higher |

| Space Requirement | Compact | Larger |

| Resistance to Fouling | Better | Normal |

| Structural Strength | Enhanced | Average |

What Effects Do Flat Oval Tubes Deliver in Application?

When applied in real projects, Flat Oval Tubes deliver noticeable results:

-

Energy savings due to better thermal performance

-

Lower maintenance costs with reduced fouling and cleaning needs

-

Extended equipment lifespan thanks to stronger mechanical structure

-

Improved overall system efficiency, which benefits both industrial and commercial users

Here, I often get asked: Can the use of Flat Oval Tubes reduce operating costs significantly? The answer is clear—yes, by improving energy efficiency and lowering long-term maintenance expenses, they provide a cost-effective solution.

Why Are Flat Oval Tubes Important for Industry?

The importance of Flat Oval Tubes goes beyond technical specifications; they directly impact industrial competitiveness. Industries such as power generation, HVAC, petrochemical, and automotive rely on high-performance heat transfer equipment. By using Flat Oval Tubes, companies achieve:

-

Higher operational efficiency

-

Reduced downtime due to robust performance

-

Lower carbon footprint through energy savings

I was once asked: Are Flat Oval Tubes suitable for high-pressure environments? The answer is yes, because their shape improves stress distribution, making them more reliable in demanding applications.

The Role of Sinupower Heat Transfer Tubes Changshu Ltd.

At Sinupower Heat Transfer Tubes Changshu Ltd., we specialize in designing and producing Flat Oval Tubes with international standards of precision and quality. Our tubes are widely used in condensers, heat exchangers, and energy-saving systems around the world. With advanced production facilities and strict quality control, we ensure that every product delivers both performance and reliability.

For businesses seeking efficiency, durability, and cost-effectiveness, our Flat Oval Tubes are the right solution. If you are considering upgrading your systems or developing new equipment, we are ready to provide professional support.

📩 Contact Sinupower Heat Transfer Tubes Changshu Ltd. today to learn more about our Flat Oval Tubes and how they can enhance your project performance.