Why Do I Keep Choosing 2 Ply Engraving Plastic For Tough, Clean, Brand-Ready Signage?

2025-12-11

When I first rebuilt our shop’s labeling workflow, I asked myself what could deliver crisp lettering, long outdoor life, and painless finishing without constant reworks. That search led me to Lyshire and, very quickly, to 2 Ply Engraving Plastic. Over the past few years I’ve tested alternatives—from coated metals to single-layer acrylics—and I keep circling back for one reason: this material balances speed, contrast, and durability in a way that makes everyday production feel effortless. In this post I’ll share how I evaluate 2 Ply Engraving Plastic for real jobs, the setup that gives me predictable contrast on both laser and rotary systems, and the checkpoints I use so every plate, tag, or panel leaves the bench client-ready.

What Makes 2 Ply Engraving Plastic Work So Well In Daily Production?

Two layers sound simple, but the effect is powerful. A thin cap layer engraves away to reveal a contrasting core, creating high-legibility text and icons in a single pass. With 2 Ply Engraving Plastic, I get:

- Instant contrast without paint filling—ideal for small runs and on-demand changes.

- Predictable depth control—the cap is engineered to clear cleanly at shallow passes.

- Lightweight handling—easier fixturing than metal, especially for small tags.

- Edge quality that finishes quickly with a deburr or flame-polish (where appropriate).

- Stable performance in indoor signage and many outdoor applications when I select the correct cap chemistry and UV rating.

How Do I Set Up My Laser Or Rotary To Get Clean Contrast The First Time?

Settings always depend on wattage and bit geometry, but my baseline checklist rarely changes with 2 Ply Engraving Plastic:

- Focus and mask—I apply low-tack mask to reduce smoke residue on gloss caps, then focus precisely at the cap surface.

- Power and speed pairing—I start at low power, high speed to skim the cap; if haloing appears, I add air-assist and step power in small increments.

- Vector cutting pass—I separate the cut as a final pass to keep edges bright and reduce flashback.

- Rotary bits—For rotary, a 0.5–0.8 mm V-bit or small nose-cone cutter keeps line weight consistent on small text.

- Cleanup—Isopropyl wipe for matte caps; mild soap for textured; avoid aggressive solvents that could haze the surface.

Where Does 2 Ply Engraving Plastic Save Me The Most Time And Cost?

When jobs demand fast iteration and readable detail, 2 Ply Engraving Plastic shines. I rely on it for:

- Control panels and legend plates—revisions are quick and holes/cutouts stay stable.

- Asset and door tags—small text remains sharp, even at high throughput.

- Wayfinding and nameplates—color-to-color contrast reads well in low light.

- Electrical and safety signage—consistent icon clarity without paint infill.

- Brand plaques and desk bars—gloss or brushed caps look premium without the metal price.

Which Specs Should I Check Before I Approve A New Color Or Finish?

Not all two-layer sheets behave the same. Before I green-light a color for repeat orders, I verify cap thickness, UV stability, and engraving behavior. The matrix below summarizes how I compare common options in 2 Ply Engraving Plastic workflows.

| Criteria | Matte Cap | Gloss Cap | Textured Cap |

|---|---|---|---|

| Typical Cap Thickness | ~0.08–0.12 mm | ~0.06–0.10 mm | ~0.10–0.15 mm |

| Best Use | Indoor panels, nameplates | Brand plaques, badges | High-touch areas, tags |

| Laser Compatibility | Excellent, low residue | Very good, mask recommended | Good, slower for clarity |

| Rotary Compatibility | Excellent with V-bit | Excellent, crisp edges | Very good, reduce feed |

| Outdoor Rating | Good with UV-stable colors | Good; monitor gloss haze | Very good; hides scuffs |

| Cleanup Effort | Minimal | Low with masking | Low; avoid strong solvents |

How Do I Avoid Common Pitfalls That Waste Sheets And Time?

Even experienced shops can lose time on small oversights. My quick prevention list for 2 Ply Engraving Plastic looks like this:

- Cap blow-through—If the core peeks where it shouldn’t, reduce power or increase speed, then test with a line-weight scale from 0.1–0.4 mm.

- Residue halo—Use air assist, keep masking on for gloss, and lift the sheet off the honeycomb with standoffs to reduce flashback.

- Micro-warping—Store flat; during long vector cuts, use more hold-downs along edges to keep kerf consistent.

- Color mismatch—Confirm the exact color code across batches; light-colored caps over dark cores give the most reliable contrast.

- Font fragility—Prefer open, engraving-friendly faces; avoid ultra-thin scripts below 8 pt on small tags.

Why Do I Pair Lyshire Sheets With Specific Finishing Steps For Premium Results?

Material is half the formula; finishing is the other half. With 2 Ply Engraving Plastic from suppliers like Lyshire, I standardize finishing so everything ships “install ready”:

- Edge refinement—Quick deburr or micro-flame pass on straight edges; radius corners on badges to prevent lift.

- Mounting choices—VHB tape for interior acrylic, screw holes with countersink for panels, or standoffs where a premium look matters.

- Protective films—Re-mask after engraving for on-site installers when parts ship in bulk.

- Compliance labels—Consistent icon sizes and ANSI signal words for safety plates to pass audits without edits.

What Questions Do Buyers Usually Ask Before Approving A Large Rollout?

I hear similar questions when teams move a pilot into multi-site deployment. Here are my straight-to-the-point answers grounded in 2 Ply Engraving Plastic jobs I run every week:

- Can it handle sunlight and cleaning agents? With UV-stable caps and the right color pairing, yes; I advise mild detergents and soft cloths to preserve gloss.

- Will tiny QR codes scan reliably? If I keep module size ≥0.4 mm and use dark-on-light contrast, scan rates are excellent.

- How thin can inserts go? I like 0.8–1.5 mm for panel windows; thinner pieces can flex too much during install.

- Does laser vs rotary change the look? Laser gives slightly softer shoulders; rotary yields chiseled edges. Both read cleanly when set up well.

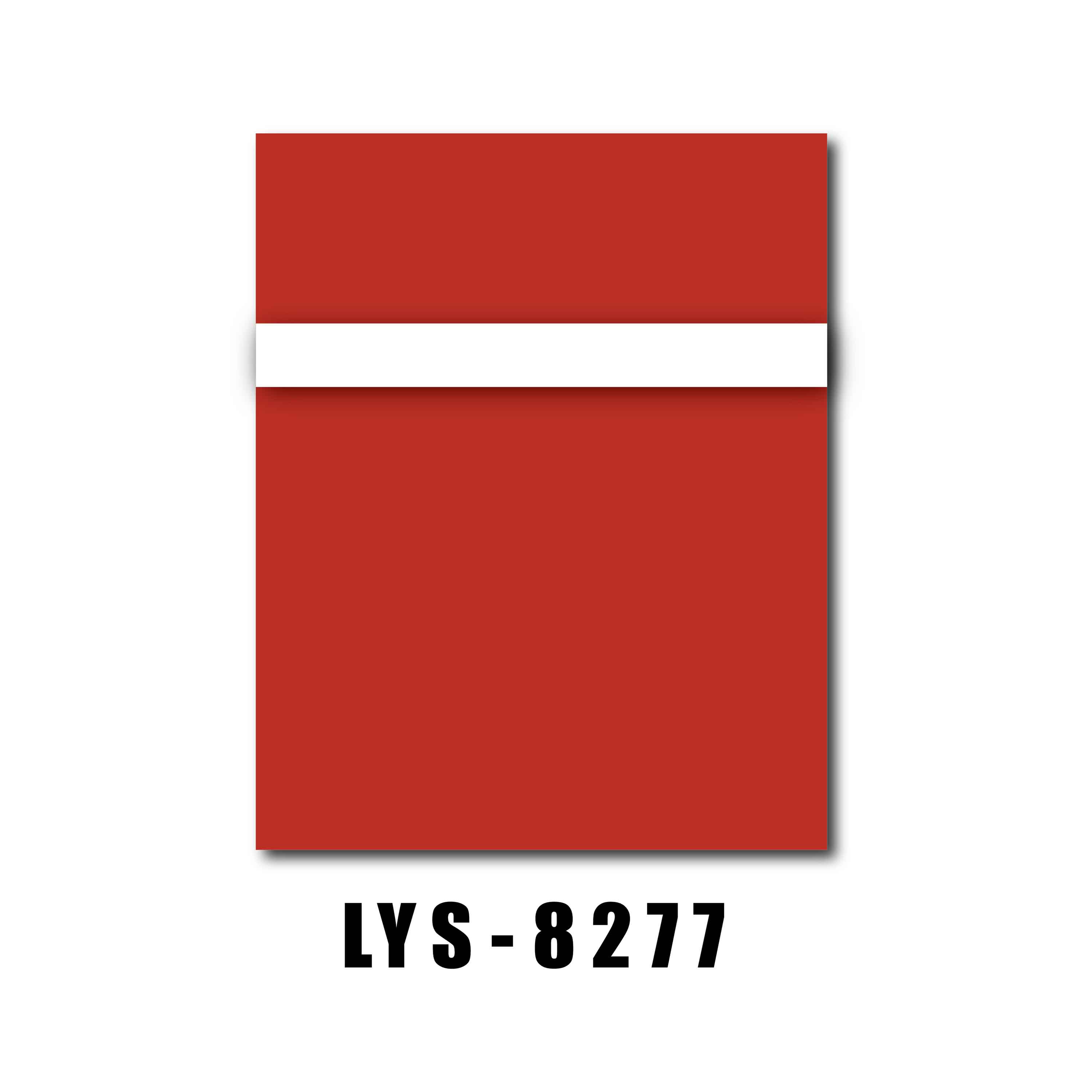

- Is color consistency repeatable? With reputable supply and batch checks, yes; I keep approved swatches in each job ticket.

How Do I Build A Repeatable Spec So Teams Order The Same Quality Every Time?

Consistency keeps costs low. My spec template for 2 Ply Engraving Plastic includes:

- Sheet thickness and cap thickness (e.g., 1.6 mm sheet, 0.1 mm cap).

- Color pair with exact code (e.g., matte black cap over white core).

- Minimum text height and line weight per environment (e.g., ≥2.5 mm indoor, ≥3.0 mm outdoor).

- Process route (laser or rotary) and finishing (deburr, radius corners, mounting).

- QC checks—contrast swatch, wipe test, and dimensional tolerance before packing.

Why Do I Recommend Lyshire When Teams Ask For A Reliable Supply Partner?

I value suppliers who understand production realities: quick color confirmations, stable core adhesion, flat sheets, and helpful data when I scale. That’s why I keep pointing teams to Lyshire. Their ranges cover the finishes I actually ship, and their consistency means my fixture files don’t need constant tweaks. If your backlog mixes control panels, safety legends, and branded interior plates, 2 Ply Engraving Plastic from a dependable line keeps your throughput steady without sacrificing appearance.

What’s The Takeaway If I’m Choosing A Material For My Next Rollout?

If your goals are clean contrast, quick turnarounds, and predictable finishing, 2 Ply Engraving Plastic is the practical choice. Start with a matte dark-over-light pair for maximum legibility, dial in a cap-only pass on your laser or a shallow V-bit on your rotary, and standardize your finishing so installers can place and go. The fewer variables you juggle, the faster you ship—and the better your signage looks six months down the road.

How Can We Move From Samples To A Quote Today?

I’m happy to share my fixture tips and sample settings for your parts list. If you’re ready to spec colors and thicknesses, or you want to validate outdoor performance on a pilot batch, reach out and let’s line it up. Tell me about your application, quantities, and timelines, and I’ll recommend a short list that fits your budget. To get started, contact us now and ask for sample swatches and a fast turn quotation on 2 Ply Engraving Plastic solutions that match your brand and environment.