Why Is a Braided Copper Tube the Quiet Upgrade Your System Might Be Missing?

2025-12-25

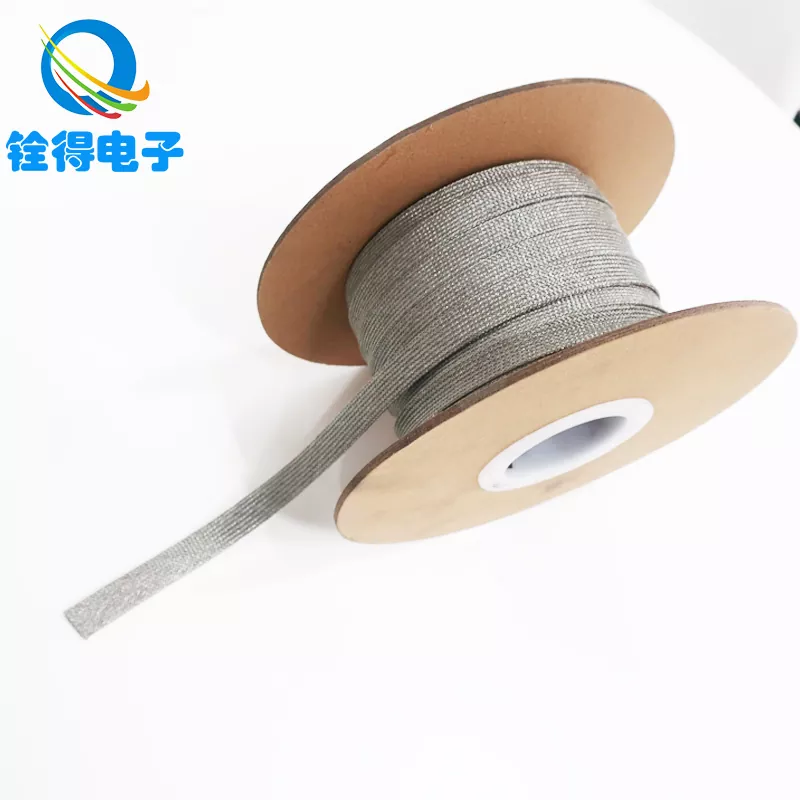

I’ve worked with enough installers, buyers, and maintenance teams to know one thing: most “tube problems” aren’t really about the tube—they’re about vibration, heat, tight routing, and the kind of real-world wear that drawings never show. When I started comparing options for flexible conductive and thermal paths, I kept coming back to what Quande makes sense of in practice: a Braided Copper Tube that’s built to handle movement without turning into a headache.

What Problems Does a Braided Copper Tube Actually Solve in the Field?

If you’re dealing with frequent rework, noisy vibration points, or premature fatigue cracks, you’re not alone. In my experience, the most common pain points look like this:

- Vibration fatigue that slowly chews through rigid connections

- Tight spaces where rigid copper is hard to route without stress

- Thermal cycling that expands and contracts joints until they loosen

- Unstable grounding or bonding when a connection can’t tolerate movement

- Maintenance downtime caused by frequent connection failures

A well-built Braided Copper Tube tackles these by combining copper’s conductivity with braided flexibility, so the connection can flex with the equipment instead of fighting it.

How Does a Braided Copper Tube Improve Reliability Without Complicating Installation?

I’m picky about anything that claims to “improve reliability,” because the tradeoff is often a harder install. The good news is that a Braided Copper Tube tends to reduce complexity in the exact places installers struggle:

- Flexible routing that follows real equipment geometry instead of forcing sharp bends

- Better stress distribution because the braid spreads load across many strands

- More forgiving alignment when components aren’t perfectly lined up

- Movement tolerance for pumps, compressors, generators, and vibrating cabinets

In short: instead of designing everything to be “perfectly still,” you accept that systems move—and you pick a connection that’s okay with that.

Which Selection Factors Matter Most When Choosing a Braided Copper Tube?

When buyers ask me what to check first, I focus on a few practical factors that directly affect service life and performance. Here’s the way I evaluate options before I recommend a spec:

| What I Check | Why It Matters | What “Good” Looks Like |

| Braid density and structure | Impacts flexibility, strength, and vibration resistance | Even, consistent braid with stable coverage |

| Copper quality and finish | Affects conductivity and corrosion resistance | Clean copper appearance with consistent strand quality |

| Tube inner/outer sizing | Determines fit, current path, and pressure/flow constraints (when applicable) | Matched to the real routing and connection hardware |

| End termination options | Controls how easy it is to assemble and how stable the connection stays | Compatible lugs/fittings with secure attachment method |

| Operating environment | Heat, humidity, salt air, oils, and vibration change the failure mode | Material/finish chosen for the site conditions |

| Quality consistency across batches | Prevents “works once, fails later” surprises | Stable manufacturing control and clear specs |

Once you define these, the “right” Braided Copper Tube usually becomes obvious—because it’s the one that fits your movement, space, and reliability targets at the same time.

Where Do I Typically See a Braided Copper Tube Perform Best?

I don’t like pretending one component is a magic solution, but there are scenarios where the braided structure is simply the most practical choice. I see strong results in:

- Grounding and bonding paths that must stay reliable under movement

- Electrical cabinets where doors, panels, or modules move during service

- Power and energy equipment with steady vibration and heat cycling

- Industrial machinery where rigid links crack or loosen over time

- Compact assemblies where routing room is limited and stress builds fast

If your current solution “works” but needs frequent tightening, replacement, or inspection, that’s usually a sign the connection is living on borrowed time.

How Can You Avoid the Most Common Purchasing Mistakes With a Braided Copper Tube?

I’ve seen the same mistakes repeat because they look harmless on paper. Here’s what I actively try to prevent when I help teams source braided copper products:

- Buying by photo instead of spec and ending up with the wrong braid density or size

- Ignoring movement and then blaming the part when the installation geometry is the real issue

- Over-optimizing cost and accepting inconsistent batches that increase downtime later

- Skipping termination details and creating weak points at the ends

- Not stating the environment so the finish and material choices don’t match the site

If you tell a supplier the true constraints—routing, bend space, movement range, and environment—you get a Braided Copper Tube that behaves predictably instead of a “maybe it’ll hold” part.

What Should You Send When Requesting a Quote So You Get the Right Braided Copper Tube Faster?

To speed things up (and avoid back-and-forth), this is what I recommend sharing in your inquiry:

- Application use case and where the tube sits in the assembly

- Required length range and any tight routing constraints

- Inner/outer sizing needs and connection interface details

- Movement or vibration expectations (even a rough description helps)

- Operating temperature and environmental exposure

- Target quantity and any repeat order expectations

With that, the supplier can match you to a Braided Copper Tube that fits your real conditions—not just a generic catalog line.

Ready to Reduce Vibration Failures With a Braided Copper Tube?

If you’re trying to cut rework, stabilize connections, or make a flexible conductive path more dependable, I’d rather you get a solution that lasts than one that “passes today.” Share your application details and I’ll help you narrow the right configuration quickly. Contact us for a quote or technical recommendation—send your specs and let’s make sure your next Braided Copper Tube order is the one you don’t have to rethink.