Why Is a Sidewall Conveyor Belt Cleat Essential for Efficient Material Handling?

2025-11-21

As industries continue to demand higher efficiency and safer transport systems, the Sidewall Conveyor Belt Cleat has become a crucial component in vertical and inclined conveying. In my daily work with Qingdao Quality Material Handling Co., Ltd., I have seen how this product significantly enhances conveying stability, reduces material rollback, and ensures smooth production flow. In this article, I will explain its functions, performance, importance, and why choosing high-quality cleats matters for long-term operation.

What Is a Sidewall Conveyor Belt Cleat?

A Sidewall Conveyor Belt Cleat is a specially engineered component designed to support bulk materials during inclined or vertical conveying. It reinforces the belt surface, prevents slippage, and increases the capacity of a conveyor system. Our cleats are made to deliver strong adhesion, high flexibility, and durability.

Functions of the Sidewall Conveyor Belt Cleat

-

Prevents material sliding or rolling back on steep conveyors

-

Enhances belt surface friction for stable conveying

-

Supports large loads and improves transportation volume

-

Works together with sidewalls to create a pocket-type conveying system

-

Ensures smooth operation under high-impact conditions

Performance & Usage Effect

The Sidewall Conveyor Belt Cleat delivers excellent results across various industries, including mining, agriculture, manufacturing, and construction. When I use cleat-reinforced belts in our production solutions, the conveying efficiency increases significantly, especially on steep or vertical setups.

Main Performance Benefits

-

High Wear Resistance – Ensures long service life

-

Strong Bonding Strength – Cleat firmly attached to the belt

-

High Flexibility – Suitable for curved or stepped conveyor designs

-

Stable Material Flow – Reduces dust, spillage, and waste

Why Is the Cleat Important in Material Handling?

The importance of the cleat lies in its ability to maintain material stability under extreme angles. It helps industries improve throughput, reduce downtime, and enhance workplace safety. As I often recommend to clients, a reliable Sidewall Conveyor Belt Cleat ensures consistent performance in both light and heavy-duty applications.

Product Parameters

| Parameter Category | Specification |

|---|---|

| Material | Rubber, PVC, PU |

| Height Range | 20mm – 500mm |

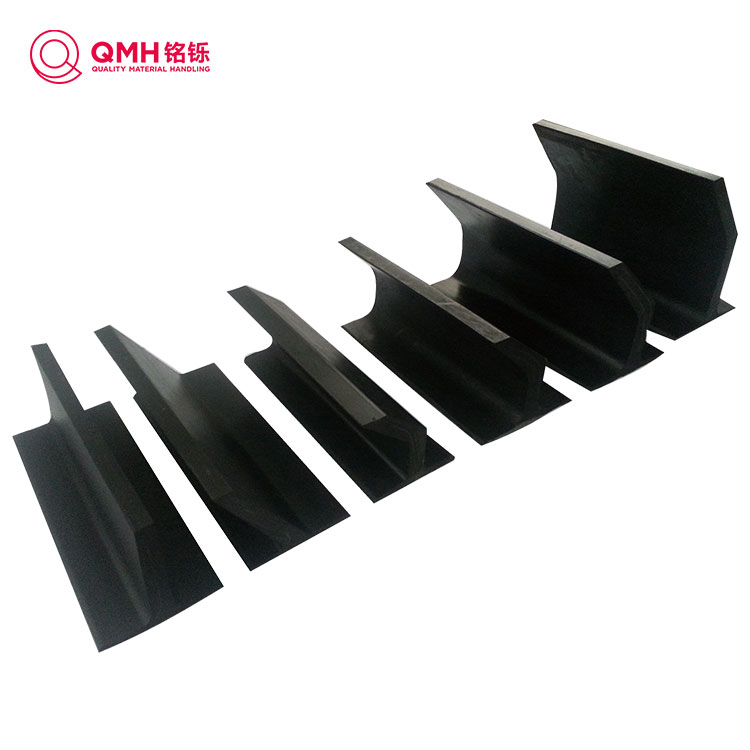

| Structure Options | T-type, C-type, L-type |

| Temperature Range | -20°C to 80°C |

| Application Angle | 0°–90° conveying |

Cleat Features

-

Heat-resistant, oil-resistant, and abrasion-resistant

-

Custom height and structure available

-

Ideal for vertical and steep-incline systems

-

Compatible with conveyor belts of different widths

-

Manufactured with precision molds for consistent quality

Three Q&A Sections

Q1: How does a Sidewall Conveyor Belt Cleat improve conveying efficiency?

A1: It increases friction and creates compartments on the belt surface, allowing materials to move without sliding, which directly boosts conveying efficiency.

Q2: Why should I choose a reinforced Sidewall Conveyor Belt Cleat for heavy-duty applications?

A2: Reinforced cleats offer greater impact resistance and longer service life, ensuring reliable performance even under high-load transport.

Q3: What industries benefit most from the Sidewall Conveyor Belt Cleat?

A3: Industries such as mining, grain handling, stone processing, and recycling all rely on cleated systems for stable vertical or inclined conveying.

Conclusion

The cleat is not just a structural component—it is a key element that determines the safety, efficiency, and cost-effectiveness of bulk material handling. With the support of Qingdao Quality Material Handling Co., Ltd., customers can achieve higher productivity and reduce operational costs through professionally engineered cleat solutions.

A Sidewall Conveyor Belt Cleat is essential for industries seeking reliable vertical or steep-incline conveying performance. From preventing rollback to improving efficiency, its advantages make it a smart investment for long-term operations. For high-quality, durable, and customizable cleat products, Qingdao Quality Material Handling Co., Ltd. is your trusted supplier—contact us today to get professional support and tailored solutions.