Why Is Flex Coagulation Material Transforming Industrial Separation Efficiency?

2025-11-21

Flex Coagulation Material is a specialized industrial medium engineered to accelerate the coagulation, separation, and purification of suspended particles in liquid systems. It is widely applied in wastewater treatment, industrial filtration, chemical processing, paper manufacturing, textile dyeing discharge, and various closed-loop water recycling systems. Its value comes from its ability to enhance particle binding, improve sedimentation rates, reduce chemical consumption, and stabilize system performance under diverse operating conditions.

At its core, Flex Coagulation Material is formulated to interact with negatively charged contaminants, bridging fine particulates into larger, easily separable flocs. By doing so, it increases filtration efficiency, reduces sludge volume, and enhances operating predictability. These performance characteristics make it a preferred solution for industries striving to meet tightening environmental regulations while reducing production costs.

Below is a concise set of typical product parameters to guide technical understanding:

| Parameter | Specification Range |

|---|---|

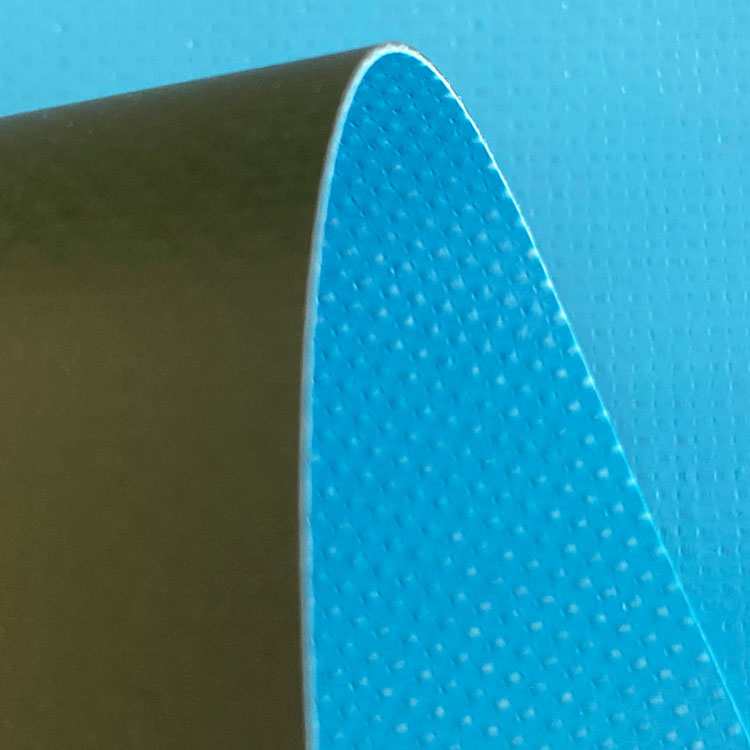

| Physical Form | Flexible porous sheet / polymeric mesh |

| Material Composition | Cross-linked polymer or composite functional media |

| Density | 0.85–1.25 g/cm³ |

| Effective Surface Area | 450–900 m²/m³ |

| pH Stability | 2–12 |

| Operating Temperature | 5–95°C |

| Coagulation Efficiency | 85–98% (depending on application) |

| Reusability Cycles | 50–200 cycles |

| Intended Applications | Wastewater treatment, chemical processing, textile effluent, paper pulp clarification, heavy-metal removal |

The following sections analyze the product through structured “what, why, how” questioning—deepening clarity for technical readers, procurement specialists, and industrial engineers.

Why Does Flex Coagulation Material Offer Distinct Advantages in Industrial Use?

Why does its structure enhance coagulation efficiency?

Flex Coagulation Material is designed with a high-porosity matrix that increases the probability of particle capture. The internal structure creates multiple collision points between suspended solids and coagulation-active surfaces. This architecture allows finer particles—often too small to settle independently—to aggregate into robust flocs.

Why does it reduce chemical consumption?

Traditional coagulation relies on large quantities of aluminum- and iron-based coagulants. Flex Coagulation Material acts as a physical and chemical facilitator, allowing smaller doses of additives to achieve the same or better results. The material’s surface properties enhance charge neutralization, minimizing the need for excessive chemical input.

Why is it more cost-effective over time?

The long reusability cycle dramatically lowers operational expenses. Instead of repeatedly dosing chemicals or replacing filter media, facilities can reuse Flex Coagulation Material multiple times before disposal. This reduces downtime, maintenance frequency, and overall waste output.

Why is it adaptable across industries?

The flexible nature allows customization in dimensions, thickness, and porosity. This supports integration into existing sedimentation basins, filtration chambers, or decentralized wastewater units without significant retrofitting. Its compatibility with various pH and temperature ranges also broadens application possibilities.

Why does it improve environmental compliance?

More efficient coagulation means fewer pollutants leaving a facility. It supports compliance with discharge regulations such as turbidity limits, COD/BOD reduction requirements, and heavy-metal thresholds. The material helps stabilize treatment output, reducing risk of environmental penalties.

How Does Flex Coagulation Material Function in Real Industrial Processes?

How does the coagulation mechanism work?

The material introduces surface-active sites that attract oppositely charged particles. As contaminated water flows through or across the medium, particles bind and form progressively larger aggregates. The flocs then settle naturally or are captured by downstream filtration units. In advanced systems, the material can also be configured to support catalytic functions, enhancing reaction efficiency.

How does it streamline industrial workflows?

-

Pre-treatment Stage:

It accelerates the initial removal of suspended solids, lowering the burden on secondary treatment steps. -

Sedimentation Phase:

Flocs formed using Flex Coagulation Material have higher density and structural integrity, improving settling speed. -

Filtration and Polishing:

Because upstream loads are reduced, final filtration units run cleaner and longer, reducing backwash frequency. -

Sludge Handling:

The compact flocs reduce sludge moisture content, simplifying dewatering and lowering transportation costs.

How does it improve operational stability?

The material reduces the impact of fluctuating influent quality. Even when particle concentration or chemical composition changes, the physical coagulation process remains effective, preventing operational interruptions.

How does it integrate with automated systems?

Modern industrial plants use sensors and automated dosing systems. Flex Coagulation Material complements automation by maintaining consistent coagulation behavior, reducing corrective adjustments and supporting predictive maintenance strategies.

How does it support sustainability goals?

With lower chemical usage, higher water recycling efficiency, and less solid waste generation, the material helps industries align with global sustainability frameworks. Its reusability also contributes to resource conservation.

What Future Trends Will Shape Flex Coagulation Material Development?

What innovations are emerging?

Future iterations are expected to incorporate:

-

Nanostructured surfaces for enhanced particle binding

-

Hybrid composite layers combining physical filtration with catalytic oxidation

-

Biodegradable polymer matrices to reduce environmental footprint

-

Smart sensing microfibers capable of monitoring floc growth in real time

These advances aim to create coagulation systems that are more intelligent, more sustainable, and more adaptive to diversified industrial demands.

What roles will automation and digital monitoring play?

Integration with real-time water-quality monitoring will allow systems to self-adjust based on turbidity, conductivity, or chemical oxygen demand. Flex Coagulation Material will likely become a central component of digitally optimized wastewater plants.

How will global environmental regulations influence product development?

Stricter regulations will require higher removal efficiency of microplastics, heavy metals, dyes, and emerging contaminants. New formulations of Flex Coagulation Material will be designed specifically to target such pollutants with improved selectivity.

How will adoption expand across industries?

Beyond traditional wastewater sectors, Flex Coagulation Material is expected to grow in:

-

Food and beverage processing

-

Pharma and biotech wastewater units

-

Mining leachate treatment

-

Semiconductor and electronics manufacturing

-

Large-scale agricultural runoff control

Growing demand for water reuse will drive broader application and innovation.

Common FAQs

Q1: What contaminants can Flex Coagulation Material effectively remove?

A: It is engineered to remove suspended solids, organic matter, dyes, colloidal particles, microplastics, and certain heavy-metal ions. Because of its large surface area and strong particle-binding capability, it performs well in varied industrial wastewater types, including high-turbidity effluent and chemically complex streams. Its performance remains stable across a wide pH and temperature range, allowing integration into multiple process designs.

Q2: How long can Flex Coagulation Material be reused before replacement?

A: Depending on operating conditions, water quality, and handling practices, it typically offers 50–200 reuse cycles. Each cycle maintains high coagulation performance with minimal degradation. Proper cleaning procedures, such as mild rinsing or controlled backwashing, extend lifespan. Its high durability significantly reduces material consumption and long-term operating costs.

Conclusion

Flex Coagulation Material plays a vital role in modern industrial treatment systems by offering high coagulation efficiency, reduced chemical demand, strong adaptability, and long-term economic benefits. Its structural design supports a broad range of applications, while future innovations are set to enhance selectivity, sustainability, and automation compatibility. The technology aligns with global demands for cleaner discharge, better water recycling, and more reliable system performance.

For high-performance industrial separation solutions, Gaoda Group provides advanced Flex Coagulation Material engineered for durability, efficiency, and stable results across multiple industries.

For more information or customized technical support, contact us.