Why Is PEEK Tubing Transforming High-Performance Engineering Applications?

2025-11-27

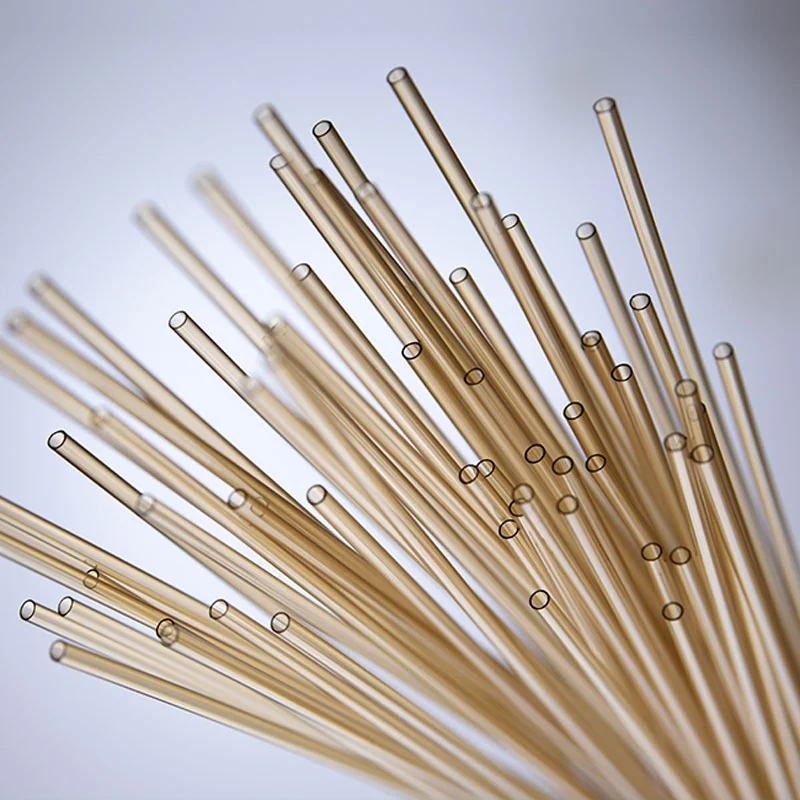

PEEK tubing, made from polyether ether ketone, is widely recognized as a premium polymer solution for industries that demand exceptional mechanical strength, chemical resistance, and long-term reliability. Its ability to maintain stability under extreme temperatures and aggressive environments has made it a preferred choice in medical devices, aerospace systems, semiconductors, oil-and-gas tools, and analytical instruments.

Unlike conventional polymer tubing, PEEK tubing withstands repeat sterilization, strong solvents, high vacuum environments, and mechanical stress without deformation. Its reliability in precision fluid transfer, micro-sampling, and insulation applications also allows engineers to replace metal tubing in corrosion-sensitive systems. The discussion below outlines the essential technical parameters that guide material selection and demonstrates how PEEK tubing continues to meet modern industry demands.

Key Technical Parameters of PEEK Tubing

| Parameter Category | Typical Specification Range | Functional Benefit |

|---|---|---|

| Temperature Resistance | -40°C to 260°C continuous | Maintains structural integrity under extreme heat |

| Tensile Strength | 90–100 MPa | High mechanical durability for demanding mechanical loads |

| Flexural Modulus | 3.6 GPa | Excellent rigidity for precision dimensional control |

| Chemical Resistance | Resistant to acids, bases, hydrocarbons, alcohols | Ideal for corrosive environments and aggressive solvents |

| Dielectric Strength | 20–25 kV/mm | High electrical insulation in aerospace and electronics |

| Inner Diameter Tolerance | ±0.01–0.03 mm depending on size | Precision fluid control and consistent flow rates |

| Surface Finish Options | Smooth, high-precision polished, micro-bore | Reduces sample carryover and system contamination |

| Available Grades | Natural PEEK, reinforced PEEK, conductive PEEK, medical-grade PEEK | Customized solutions for structural, sterile, or anti-static requirements |

These parameters collectively define how PEEK tubing performs in real-world environments and why it continues to replace traditional metal and fluoropolymer solutions in high-precision systems.

Why Do Engineers Choose PEEK Tubing Over Metal or Fluoropolymer Alternatives?

PEEK tubing continues expanding across modern manufacturing due to its rare ability to provide high performance without the weight or manufacturing limitations associated with metal tubing. Engineers rely on its combination of strength, purity, and processability to improve system efficiency while lowering lifetime maintenance costs.

Why PEEK Tubing Stands Out

1. Exceptional Temperature and Pressure Stability

PEEK’s semi-crystalline structure allows it to perform continuously at high temperatures while maintaining dimensional accuracy. In systems such as chromatography, oil-well instruments, or aerospace fuel lines, temperature cycling can weaken conventional polymers. PEEK, however, maintains strength and avoids stress cracking over long operational cycles.

2. Long-Term Chemical and Solvent Resistance

Unlike stainless steel, PEEK is immune to chloride-induced corrosion and most organic solvents. It prevents ion leaching and metal contamination, making it particularly valuable in pharmaceutical sampling, semiconductor wet processes, and analytical instruments where purity is essential.

3. Lightweight Replacement for Metals

PEEK’s strength-to-weight ratio makes it highly attractive in aerospace and automotive applications. It provides mechanical performance comparable to aluminum and other lightweight metals, while eliminating corrosion and simplifying routing in tight installation environments.

4. Biocompatibility for Medical and Life-Science Devices

Medical-grade PEEK complies with ISO 10993 standards, enabling its use in catheters, surgical tools, and implantable components. It withstands repeated sterilization cycles, including autoclave, gamma, and EtO processes.

5. Precision Extrusion for Micro-Bore Applications

PEEK tubing can be manufactured in extremely small diameters—the kind required in microfluidics, HPLC, laboratory automation, and integrated diagnostic systems. Its dimensional consistency ensures stable flow rates and minimal pulsation in precision measurement instruments.

Typical Applications Across Key Industries

-

Medical & Life Sciences: catheters, microfluidic channels, biopsy systems

-

Analytical Instruments: HPLC tubing, sample transfer lines, solvent-resistant flow paths

-

Aerospace: insulation tubing, fuel-handling components, high-temperature wire covers

-

Semiconductor Manufacturing: chemical delivery lines, etching processes

-

Oil & Gas: downhole tools, high-temperature sensing equipment

-

Automotive: lightweight fluid delivery tubes, EV insulation sleeves

These application scenarios highlight why PEEK tubing remains an essential material where failure is not an option.

How Is PEEK Tubing Manufactured and Optimized for Precision Performance?

The performance of PEEK tubing depends heavily on advanced manufacturing techniques. From resin selection to final quality inspection, production requires strict control over purity, dimensional accuracy, and mechanical consistency.

How High-Quality PEEK Tubing Is Produced

1. Material Selection and Resin Purification

Manufacturers begin by evaluating the grade of PEEK resin required for the application. Medical and semiconductor applications demand ultra-low extractables, while aerospace and structural applications may incorporate reinforced or conductive PEEK.

2. Precision Extrusion

PEEK resin is heated to a molten state, then extruded through precision dies to form tubing with consistent wall thickness. Maintaining thermal stability is essential to prevent crystallinity variations that could affect strength, elongation, and dimensional accuracy.

3. Controlled Cooling and Annealing

After extrusion, the tubing undergoes controlled cooling to stabilize molecular structures. Optional annealing improves mechanical strength and reduces internal stress—critical for high-pressure or long-term applications.

4. Surface Finishing and Micro-Polishing

Some applications, especially in chromatography or micro-sampling, require extremely smooth inner surfaces. Micro-polishing reduces friction, minimizes adsorption of analytes, and ensures cleaner flow paths.

5. Quality Inspection and Dimensional Testing

Advanced laser-based systems verify inner diameter, wall thickness, ovality, and surface uniformity. Tubing may also undergo pressure tests, chemical exposure simulations, and thermal cycling trials to ensure long-term reliability.

Common Questions About PEEK Tubing

Q1: Can PEEK tubing replace stainless steel in high-pressure systems?

A1: Yes, PEEK tubing can replace stainless steel in many mid- to high-pressure systems, depending on wall thickness and grade. Reinforced PEEK can handle substantial pressures while eliminating corrosion and metal-ion contamination. For ultra-high pressures, thicker-wall configurations or hybrid assemblies may be used.

Q2: How does PEEK tubing perform in long-term chemical exposure?

A2: PEEK tubing is highly resistant to most acids, bases, hydrocarbons, alcohols, and organic solvents. It maintains mechanical stability during continuous chemical exposure, making it ideal for analytical instruments, semiconductor wet processes, and industrial chemical delivery systems.

These questions illustrate the practical considerations most engineers evaluate when choosing high-performance polymer tubing.

What Trends Will Shape the Future of PEEK Tubing in Advanced Engineering?

Rapid progress across medical technology, electric vehicles, aerospace electrification, and semiconductor manufacturing is increasing the demand for high-performance polymers capable of outperforming metals. Several major trends are shaping the future of PEEK tubing.

Key Industry Trends Driving PEEK Tubing Adoption

1. Miniaturization and Microfluidics

Modern diagnostic devices and laboratory automation platforms require ultra-thin, micro-bore tubing with exceptional dimensional stability. PEEK’s processability enables development of micro-channels that maintain flow precision even at high temperatures.

2. Electrification and High-Voltage Insulation

As electric vehicles and aerospace systems expand electrified components, PEEK’s excellent dielectric properties make it an essential material for insulation tubes, battery management components, and high-voltage routing systems.

3. Replacement of Metals in Corrosion-Critical Applications

Industries are shifting away from stainless steel in areas exposed to aggressive chemicals. PEEK tubing provides a long-term, corrosion-free alternative with lower maintenance cost and better chemical purity.

4. Growth of Biocompatible and Home-Care Medical Devices

The shift toward minimally invasive devices, portable care systems, and implantable components increases demand for medical-grade PEEK tubing that can tolerate sterilization and prolonged body-contact environments.

5. Sustainability and Longer Product Lifespan

PEEK’s durability allows manufacturers to extend system lifespan, reduce part replacement frequency, and minimize waste—important for sustainability-focused engineering teams.

PEEK tubing continues to influence the future of advanced engineering due to its exceptional thermal stability, mechanical strength, chemical resistance, and versatility across high-performance systems. From medical and analytical applications to aerospace and semiconductor processing, PEEK tubing provides an ideal balance of durability, precision, and purity. Its growing adoption is tied to global trends such as electrification, miniaturization, material replacement strategies, and higher standards for system reliability.

For organizations seeking consistent quality and engineering-grade performance, Ningbo Micro-tube Polymer Materials Co., Ltd. offers tailored PEEK tubing solutions built on strict material control and advanced extrusion technology. For detailed specifications, custom sizes, or application guidance, contact us to discuss how high-performance PEEK tubing can enhance your system design.