Why Is the Aluminum Flat Oval Welded Tube for Radiators the Ideal Choice for Modern Heat Exchange Systems?

2025-10-21

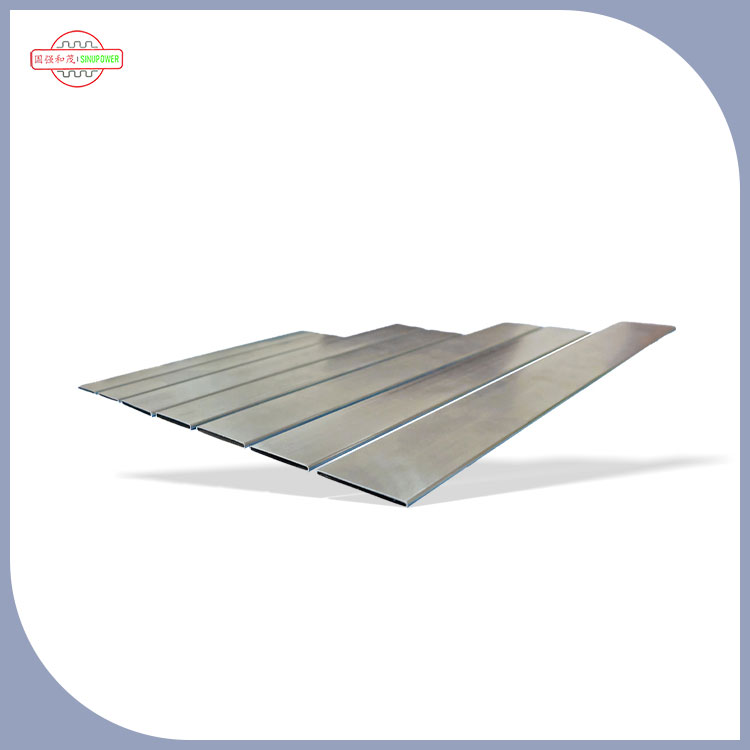

When it comes to maximizing the performance and efficiency of modern radiators, the Aluminum Flat Oval Welded Tube for Radiators stands out as a highly reliable and technologically advanced solution. With the growing need for lightweight, durable, and high-thermal-conductivity materials, aluminum tubes have become a preferred choice for many radiator manufacturers. Their special oval design improves heat dissipation efficiency, reduces pressure loss, and ensures smooth fluid flow within the system.

At Sinupower Heat Transfer Tubes Changshu Ltd., we specialize in producing precision-engineered aluminum welded tubes that meet international standards and serve diverse industries—from automotive to HVAC and industrial heat exchangers.

The Role of Aluminum Flat Oval Welded Tubes in Radiators

The Aluminum Flat Oval Welded Tube for Radiators plays a crucial role in improving the overall heat transfer efficiency of the radiator system. Its flat-oval cross-section provides a larger contact area with cooling fins while minimizing air resistance. This structural optimization enhances the radiator's ability to dissipate heat, making it ideal for high-performance and energy-efficient systems.

Moreover, the aluminum material provides excellent corrosion resistance, ensuring long-term stability even under extreme environmental conditions. The tube's welded structure ensures airtightness and strength, supporting stable performance in both automotive and industrial cooling systems.

Technical Parameters

| Parameter | Specification Range |

|---|---|

| Material | High-grade Aluminum Alloy (3003 / 6063) |

| Outer Diameter (mm) | 10.0 – 40.0 |

| Wall Thickness (mm) | 0.8 – 2.5 |

| Shape | Flat Oval (Customized available) |

| Surface Treatment | Mill Finish / Polished / Anodized |

| Welding Method | High-Frequency Welding |

| Application | Radiators, Condensers, Intercoolers, HVAC |

| Manufacturer | Sinupower Heat Transfer Tubes Changshu Ltd. |

These parameters are designed to ensure optimal compatibility with various radiator systems while maintaining excellent performance and longevity.

What Are the Main Effects of Using Aluminum Flat Oval Welded Tubes?

The main effects of using Aluminum Flat Oval Welded Tube for Radiators are enhanced heat transfer, lower system weight, and improved corrosion resistance. The flat oval shape increases airflow efficiency and heat dissipation capacity, making radiators smaller yet more powerful.

From my professional experience, I have seen how clients benefit from improved cooling efficiency—whether in vehicles or industrial systems—after switching to our aluminum welded tubes. This results in reduced energy consumption and improved product durability.

Why Do I Recommend the Aluminum Flat Oval Welded Tube for Radiators?

I often get asked: Why should we choose aluminum flat oval welded tubes over traditional copper or round steel tubes?

The answer lies in the balance of weight, strength, and heat conductivity. Aluminum offers an excellent combination of these properties at a lower cost. Its welded oval design allows for better thermal performance and less pressure drop compared to round tubes. Additionally, aluminum is recyclable, making it an environmentally sustainable option for future-oriented industries.

What Makes Sinupower Heat Transfer Tubes Changshu Ltd. a Trusted Supplier?

I believe that trust comes from consistent quality and technical innovation. At Sinupower Heat Transfer Tubes Changshu Ltd., we focus on precision manufacturing, quality control, and R&D innovation. Each Aluminum Flat Oval Welded Tube for Radiators is produced using advanced high-frequency welding technology and undergoes strict testing to ensure airtightness, mechanical strength, and corrosion resistance.

We serve global customers in the automotive, aerospace, and industrial heat exchange sectors, providing both standard and customized solutions.

The Importance of Aluminum Flat Oval Welded Tubes

The importance of the Aluminum Flat Oval Welded Tube for Radiators lies in its ability to make heat exchange systems lighter, more efficient, and more cost-effective. Its superior thermal conductivity enables faster heat transfer, improving radiator performance while reducing the amount of material used.

Additionally, aluminum tubes are easy to form, weld, and recycle, aligning with the sustainability goals of modern manufacturing. This makes them not just a practical choice but also an environmentally responsible one.

Frequently Asked Questions (FAQ)

Q1: What advantages does the Aluminum Flat Oval Welded Tube for Radiators have over round tubes?

A1: Its flat oval design improves heat dissipation, reduces air resistance, and allows for more compact radiator designs.

Q2: Can these tubes be customized for specific applications?

A2: Yes. At Sinupower Heat Transfer Tubes Changshu Ltd., we offer customized dimensions, materials, and surface finishes according to client requirements.

Q3: How durable are aluminum welded tubes compared to copper or steel?

A3: Aluminum welded tubes are lightweight, corrosion-resistant, and durable, offering long-term performance even in harsh environments.

Q4: Are aluminum flat oval welded tubes suitable for both automotive and industrial radiators?

A4: Absolutely. They are widely used in automotive radiators, HVAC systems, and industrial heat exchangers due to their excellent heat transfer and pressure resistance.

Conclusion

In conclusion, the Aluminum Flat Oval Welded Tube for Radiators represents the next generation of efficient, durable, and sustainable heat transfer solutions. Its optimized shape, strong welding integrity, and superior thermal performance make it an ideal choice for industries seeking innovation and reliability.

If you are looking for high-performance heat transfer tubes, Sinupower Heat Transfer Tubes Changshu Ltd. is your trusted partner.

👉 For inquiries, specifications, or quotations, please contact us today — let's build a more efficient future together!