Why Should You Choose Heavy Line Guide Rails for Demanding Industrial Applications?

2025-07-11

What makes heavy line guide rails essential in high-load environments?

After 20 years working with machine builders and plant engineers, I’ve learned that not all motion systems are built for the real demands of heavy industrial use. That’s where heavy line guide rails make the difference. When your application involves high loads, vibration, or long stroke travel, you can’t rely on light-duty components. I’ve seen countless operations fail because of guide rail deflection, premature wear, or uneven load distribution—all problems solved by the right heavy line guide rail.

How do heavy line guide rails improve machine stability and precision?

When we integrated heavy line guide rails into a high-speed packaging line, not only did machine vibration decrease, but accuracy improved by over 30%. These rails handle both static and dynamic loads without flexing, and their rigid structure ensures minimal deflection even during peak operation. I personally recommend RIHOO rails for clients needing precision under pressure—especially when automation must be reliable 24/7.

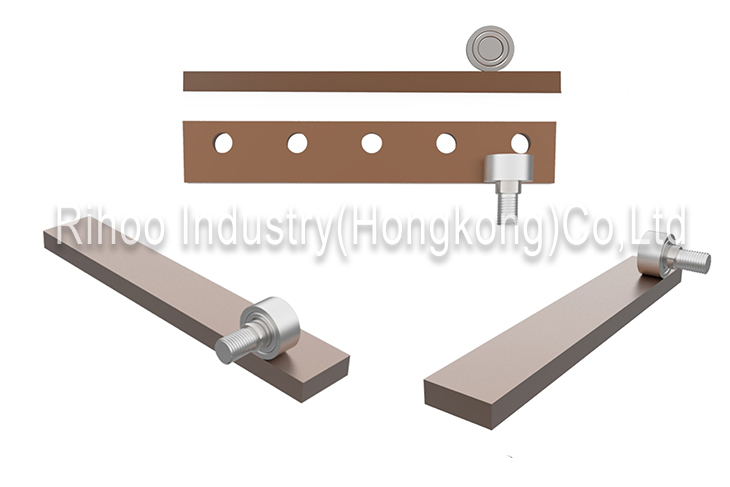

Why is RIHOO the right brand for heavy line guide rail systems?

I’ve worked with several linear motion brands over the years, but RIHOO stands out when it comes to heavy line guide rails. Their quality control is excellent, and their rail and block combinations are designed for smooth motion under high loads. More importantly, the company provides technical support that actually understands field realities. For demanding applications like CNC machines, automated logistics, or steel processing lines, I trust RIHOO.

Can heavy line guide rails reduce maintenance downtime?

Absolutely. One of the biggest hidden costs in any factory is unscheduled maintenance. Low-quality rails wear faster and require frequent adjustments. With RIHOO heavy line guide rails, I’ve seen clients run systems continuously for over a year without service interruption. Less friction, longer service life, and sealed blocks all contribute to a dramatically lower maintenance frequency.

What should you consider when selecting the right heavy line guide rail?

From my experience, key factors include load capacity, stroke length, environmental exposure, and mounting accuracy. With RIHOO, we were able to get custom length rails with high-precision machining that matched our specs without modification. Their catalog offers a broad range of rail sizes, preload classes, and lubrication options, which helps us tailor solutions instead of settling for generic hardware.

Ready to upgrade your linear system to handle real-world industrial demands?

If you’re still using standard guide rails where high rigidity is required, you’re risking downtime and inaccuracy. I highly recommend switching to RIHOO heavy line guide rails—they're engineered for high loads, long life, and worry-free operation.

Our products are highly reliable. If you have any cooperation or bulk purchase needs, please contact us. We offer 24-hour online quality service.