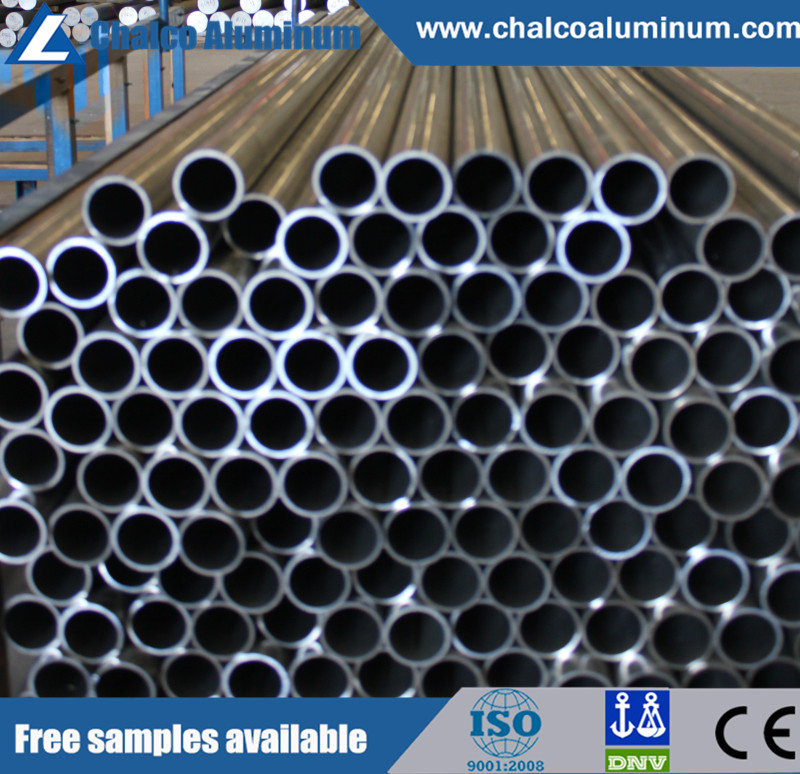

Aluminum and Aluminium Tube Pipe (6005/6105/ 6041 /6042)

Aluminum and Aluminium Tube Pipe (6005/6105/6041/6042) 6005 alloy is widely used for extrusion of general aluminum material. All extruded sections and pipes that require material strength more than 6063 alloy can be produced by this alloy. Like 6063 alloy, they are pure Al-Mg-Si alloy. Except Mg and......

Send Inquiry

Product Description

Aluminum and Aluminium Tube Pipe (6005/6105/6041/6042)

6005 alloy is widely used for extrusion of general aluminum material. All extruded sections and pipes that require material strength more than 6063 alloy can be produced by this alloy. Like 6063 alloy, they are pure Al-Mg-Si alloy. Except Mg and Si, no alloying elements are contained, Mg2Si is the only strengthening phase, and all Mg and Si form Mg2Si. It has excellent extrusion performance and low quench sensitivity, and can be used for on-line quenching of the extruder. The material with wall thickness less than 3mm can be air-cooled quenching. Another prominent advantage of them is the smooth surface and easy anodizing and coloring. 6005 alloys are currently widely used for extruding sections and pipes of products such as ladders, wheelchairs, television antennas, and platform frames. However, it should be noted that 6005 alloys are not made to bear the impact load structure.

6005 alloy is widely used for extrusion of general aluminum material. All extruded sections and pipes that require material strength more than 6063 alloy can be produced by this alloy. Like 6063 alloy, they are pure Al-Mg-Si alloy. Except Mg and Si, no alloying elements are contained, Mg2Si is the only strengthening phase, and all Mg and Si form Mg2Si. It has excellent extrusion performance and low quench sensitivity, and can be used for on-line quenching of the extruder. The material with wall thickness less than 3mm can be air-cooled quenching. Another prominent advantage of them is the smooth surface and easy anodizing and coloring. 6005 aluminum tube pipe are currently widely used for extruding sections and pipes of products such as ladders, wheelchairs, television antennas, and platform frames. However, it should be noted that 6005 alloys are not made to bear the impact load structure.

Specification:

Alloy: 6005 6105 6041 6042

Temper: T1,T5,T6511

OD: 3--130mm

ID: 3--100mm

Length: 1000mm--6000mm

6005 alloy is widely used for extrusion of general aluminum material. All extruded sections and pipes that require material strength more than 6063 alloy can be produced by this alloy. Like 6063 alloy, they are pure Al-Mg-Si alloy. Except Mg and Si, no alloying elements are contained, Mg2Si is the only strengthening phase, and all Mg and Si form Mg2Si. It has excellent extrusion performance and low quench sensitivity, and can be used for on-line quenching of the extruder. The material with wall thickness less than 3mm can be air-cooled quenching. Another prominent advantage of them is the smooth surface and easy anodizing and coloring. 6005 alloys are currently widely used for extruding sections and pipes of products such as ladders, wheelchairs, television antennas, and platform frames. However, it should be noted that 6005 alloys are not made to bear the impact load structure.

6005 alloy is widely used for extrusion of general aluminum material. All extruded sections and pipes that require material strength more than 6063 alloy can be produced by this alloy. Like 6063 alloy, they are pure Al-Mg-Si alloy. Except Mg and Si, no alloying elements are contained, Mg2Si is the only strengthening phase, and all Mg and Si form Mg2Si. It has excellent extrusion performance and low quench sensitivity, and can be used for on-line quenching of the extruder. The material with wall thickness less than 3mm can be air-cooled quenching. Another prominent advantage of them is the smooth surface and easy anodizing and coloring. 6005 aluminum tube pipe are currently widely used for extruding sections and pipes of products such as ladders, wheelchairs, television antennas, and platform frames. However, it should be noted that 6005 alloys are not made to bear the impact load structure.

Specification:

Alloy: 6005 6105 6041 6042

Temper: T1,T5,T6511

OD: 3--130mm

ID: 3--100mm

Length: 1000mm--6000mm

| Chemical Composition | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ga | V | Ti | Other | Min.Al |

| 6005 | 0.6-0.9 | 0.35 | 0.10 | 0.10 | 0.40-0.60 | 0.10 | - | 0.10 | - | - | 0.10 | 0.15 | Remainder |

| 6105 | 0.6-1.0 | 0.35 | 0.10 | 0.10 | 0.45-0.8 | 0.1 | - | 0.1 | - | - | 0.1 | 0.15 | Remainder |

| 6041 | 0.5-0.9 | 0.15-0.70 | 0.15-0.60 | 0.05-0.20 | 0.8-1.2 | 0.05-0.15 | - | 0.25 | - | - | 0.15 | 0.15 | Remainder |

| 6042 | 0.5-1.2 | 0.70 | 0.2-0.6 | 0.40 | 0.7-1.2 | 0.04-0.35 | - | 0.25 | - | - | 0.15 | 0.15 | Remainder |

| Physical Property | ||||||

| Alloy | Temper | Wall thickness /mm | Room temperature Test Result | |||

| Tension Strength/MPa | Yield Strength/MPa | Elongation/% | ||||

| A50mm | A | |||||

| Not less than | ||||||

| 6005 | T1 | ≤12.50 | 170 | 105 | 16 | 14 |

| T5 | ≤3.20 | 260 | 240 | 8 | - | |

| 3.20~25.00 | 260 | 240 | 10 | 9 | ||

| 6105 | T1 | ≤12.50 | 170 | 105 | 16 | 14 |

| T5 | ≤12.50 | 260 | 240 | 8 | 7 | |

| 6041 | T5,T6511 | 10.00~50.00 | 310 | 275 | 10 | 9 |

| 6042 | T5,T6511 | 10.00~12.50 | 260 | 240 | 10 | - |

| 12.50~50.00 | 290 | 240 | - | 9 | ||

Related Category

Wire Mesh

Pipe Fittings

Building Glass

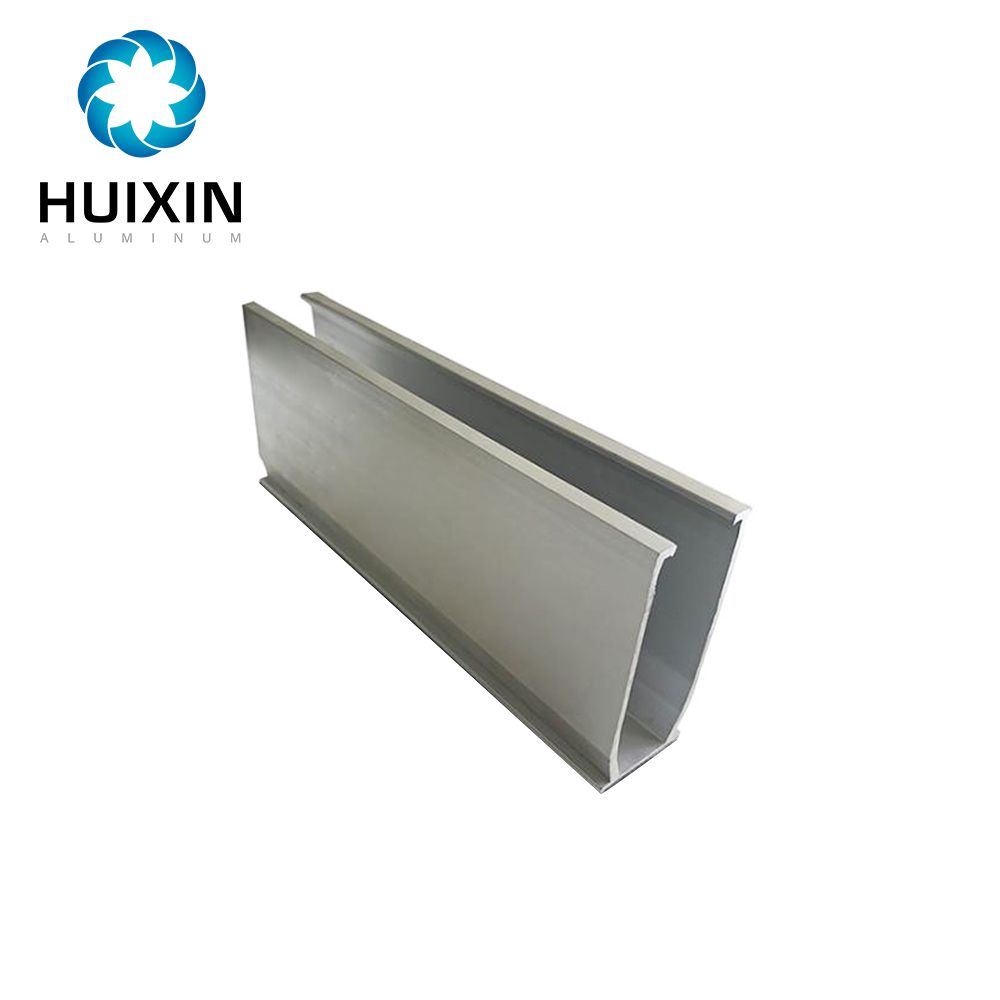

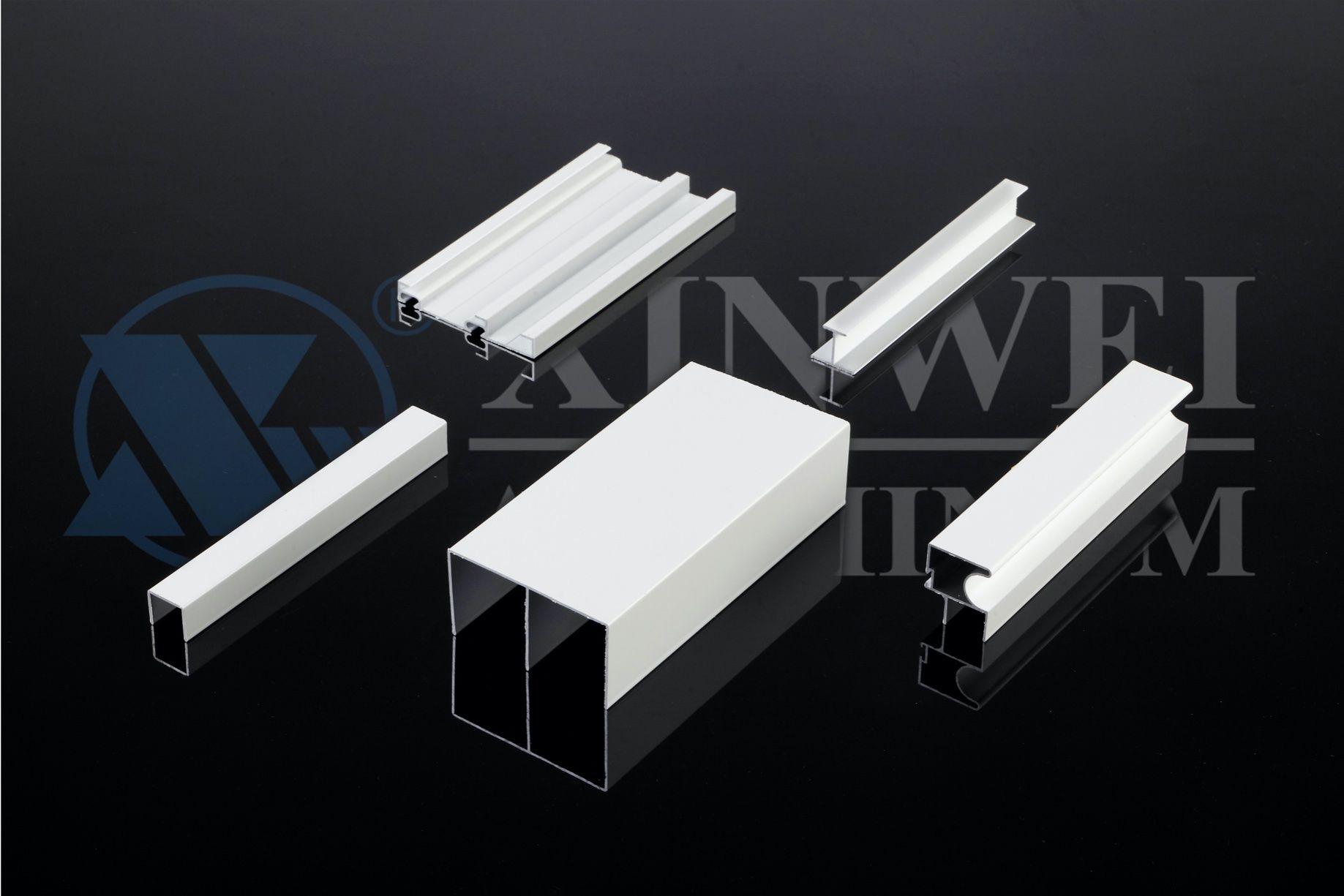

Aluminum Profile

Plywood

Window

Ceiling

Mirror

Aluminum Composite Panel

Wallpaper

Fireplace, Stove & Parts

Composite Pipe & Tube

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.