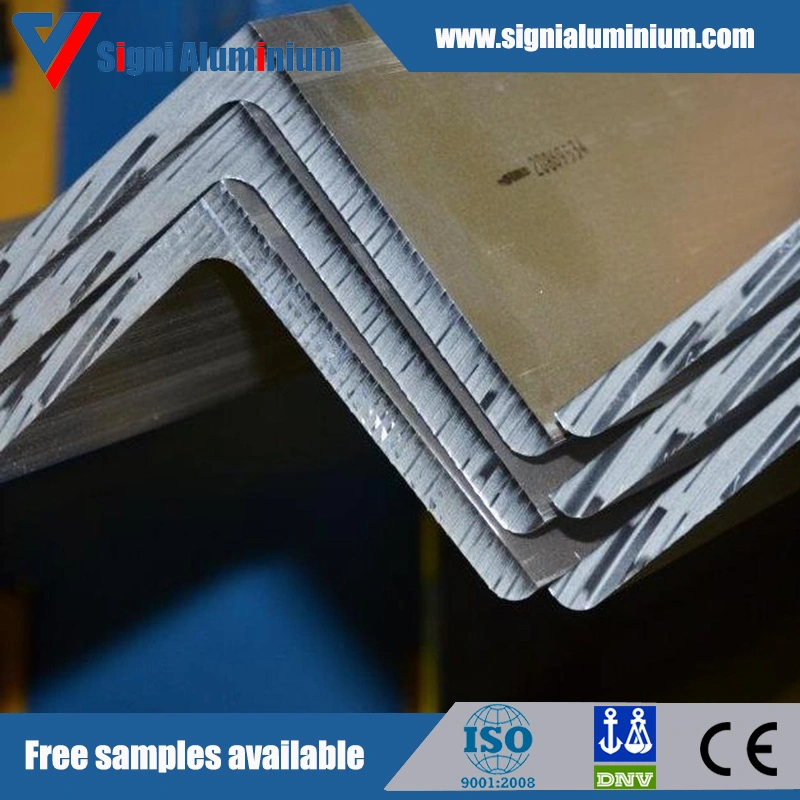

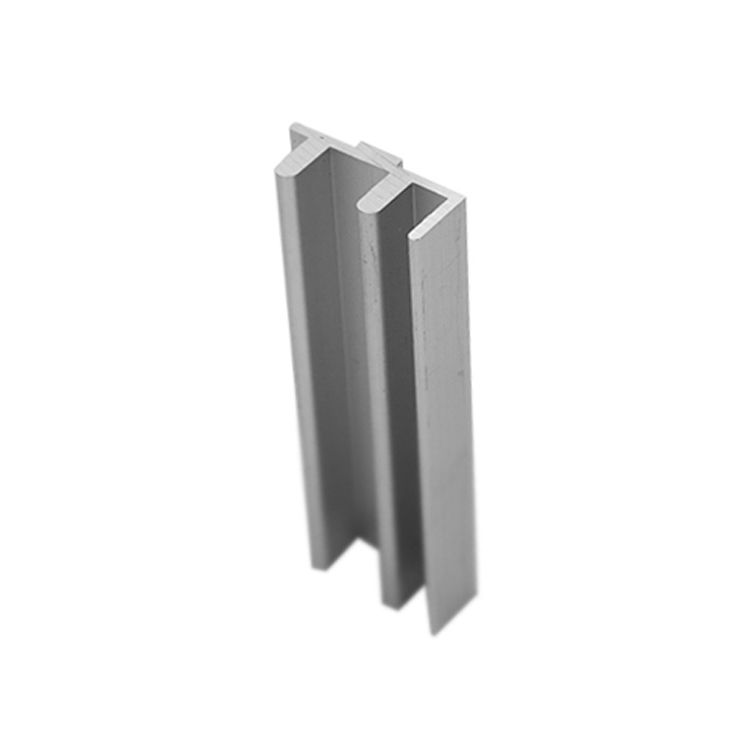

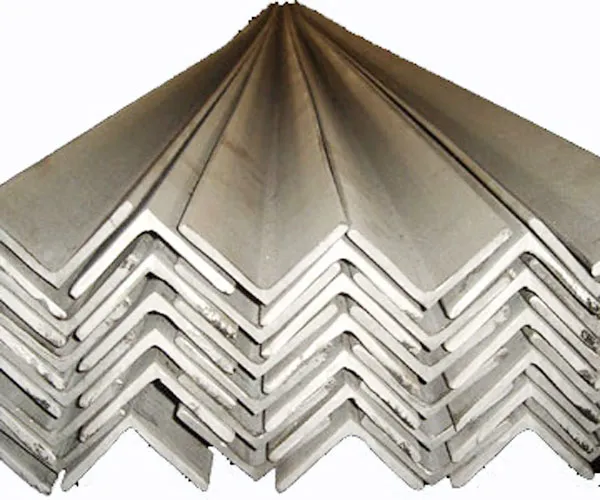

Marine Grade Aluminum Angle Bar ( 5083 /5086/5383//6061/6082)

Marine Grade Aluminum Angle Bar (5083/5086/5383//6061/6082)5083 and 5086 are non heat treatable alloys. The mechanical properties of the alloy depend on the chemical composition of the alloy and the hot rolling temperature. The supply status of marine 5083 and 5086 alloy is O, H111 and H112. Among t......

Send Inquiry

Product Description

Marine Grade Aluminum Angle Bar (5083/5086/5383//6061/6082)

5083 and 5086 are non heat treatable alloys. The mechanical properties of the alloy depend on the chemical composition of the alloy and the hot rolling temperature. The supply status of marine 5083 and 5086 alloy is O, H111 and H112. Among them, the latter is resistant to stress corrosion, and can prevent the tropical climate from intergranular corrosion cracking.

6061 and 6082 aluminum alloys are widely used as light structural materials and widely used in transportation materials. 6061 and 6082 alloy extrusion products need any double base heat treatment for age hardening. The working procedure is as follows: heating billet, extrusion, profile quenching, solid solution treatment, straightening, aging in furnace. Only by strictly controlling the technological parameters of each process can a satisfactory mechanical performance be achieved.

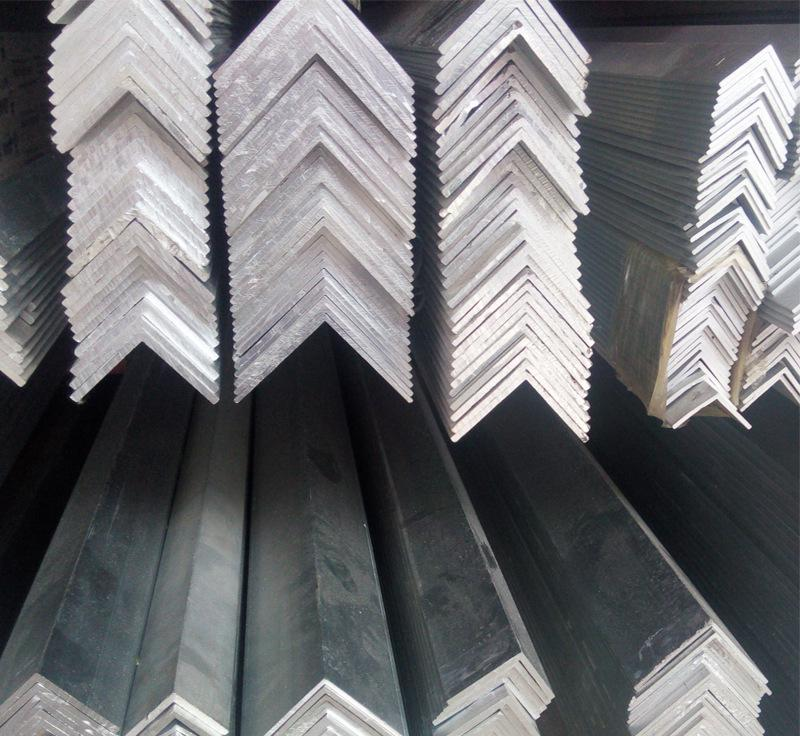

Marine Aluminum Angle Bar Specification

Alloy: 5083, 5086, 5383, 5059, 6061, 6082,6005A

Temper: H111/H112, T5/T6

Certificate: BV /DNV /ABS/Lioyds

Thickness: 3mm---50mm

Marine Aluminum Angle Bar Mould List

5083 and 5086 are non heat treatable alloys. The mechanical properties of the alloy depend on the chemical composition of the alloy and the hot rolling temperature. The supply status of marine 5083 and 5086 alloy is O, H111 and H112. Among them, the latter is resistant to stress corrosion, and can prevent the tropical climate from intergranular corrosion cracking.

6061 and 6082 aluminum alloys are widely used as light structural materials and widely used in transportation materials. 6061 and 6082 alloy extrusion products need any double base heat treatment for age hardening. The working procedure is as follows: heating billet, extrusion, profile quenching, solid solution treatment, straightening, aging in furnace. Only by strictly controlling the technological parameters of each process can a satisfactory mechanical performance be achieved.

Marine Aluminum Angle Bar Specification

Alloy: 5083, 5086, 5383, 5059, 6061, 6082,6005A

Temper: H111/H112, T5/T6

Certificate: BV /DNV /ABS/Lioyds

Thickness: 3mm---50mm

| Marine Aluminum Angle Bar Aluminum Alloys Composition | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | Others | Alu | |

| Each | Toal | ||||||||||||

| 5083 | 0.40 | 0.40 | 0.1 | 0.4-1.0 | 4.0--4.9 | 0.05--0.25 | -- | 0.25 | 0.15 | -- | 0.05 | 0.15 | Remainder |

| 5383 | 0.25 | 0.25 | 0.20 | 0.7-1.0 | 4.0-5.2 | 0.25 | -- | 0.40 | 0.15 | -- | 0.05 | 0.15 | Remainder |

| 5086 | 0.40 | 0.50 | 0.1 | 0.2--0.7 | 3.5-4.5 | 0.05-0.25 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 5059 | 0.45 | 0.50 | 0.25 | 0.6-1.2 | 5.0-6.0 | 0.25 | - | 0.40-0.9 | 0.20 | - | 0.05 | 0.15 | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 6005A | 0.50-0.9 | 0.35 | 0.30 | 0.50 | 0.40-0.7 | 0.30 | - | 0.20 | 0.10 | - | 0.05 | 0.15 | Remainder |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.25 | - | 0.20 | 0.10 | - | 0.05 | 0.15 | Remainder |

| Mechanical Properties of Marine Aluminum Angle Bar | |||||||

| Alloy | Form | Thickness(mm) | Temper | Rm | Rp0.2 (Mpa) | A% Min | |

| Min. | A | A | |||||

| 5086 | Shapes, Bar, Tube | 3≤t≤50 | H112 | 240 | 95 | 10 | 12 |

| 5083 | Shapes, Bar, Tube Shapes, Bar, Tube | 3≤t≤50 3≤t≤50 | H111 O and H112 | 270 270 | 110 125 | 10 10 | 12 12 |

| 5059 | Shapes, Bar, Tube | 3≤t≤50 | H112 | 330 | 200 | 10 | |

| 5383 | Shapes, Bar, Tub | 3≤t≤50 | O | 290 | 145 | 17 | 17 |

| Shapes, Bar, Tub | 3≤t≤50 | H112 | 310 | 190 | 13 | ||

| 6061 | Shapes, Bar, Tube Profiles | 3≤t≤50 3≤t≤50 | T5 or T6 T5 or T6 | 260 245 | 240 205 | 10 | 8 4 |

| 6005A | Shapes, Bar, Tube Profiles | 3≤t≤50 | T5 | 260 | 215 | 9 | 8 |

| Shapes, Bar, Tube Profiles | 3≤t≤10 | T6 | 260 | 215 | 8 | 6 | |

| 10≤t≤50 | 250 | 200 | 8 | 6 | |||

| 6082 | Shapes, Bar, Tube Closed shapes | 3≤t≤50 3≤t≤50 | T5 or T6 T5 or T6 | 310 290 | 260 240 | 10 | 8 5 |

Marine Aluminum Angle Bar Mould List

| Material Code | A(mm) | B(mm) | T(mm) | R1 | R2 | Kg/m |

| TP-179 | 7 | 19.5 | 1.00 | 0.069 | ||

| TP-939 | 8 | 12 | 2.00 | 0.13 | ||

| CAM_A000026 | 10 | 15 | 1.00 | 0.065 | ||

| CAM_A000185 | 10 | 15 | 2.00 | 0.124 | ||

| TP-500 | 10 | 20 | 1.20 | 0.116 | ||

| ALD_D001982 | 10 | 20 | 1.60 | 0.123 | ||

| CAM_A000321 | 10 | 20 | 2.00 | 0.151 | ||

| CAM_A000586 | 10 | 25 | 2.00 | 0.178 | ||

| CAM_A000188 | 10 | 30 | 2.00 | 0.205 | ||

| CAM_A000192 | 10 | 40 | 2.00 | 0.259 | ||

| CAM_A000767 | 10 | 45 | 2.00 | 0.286 | ||

| AUS_D000747 | 12 | 20 | 1.20 | 0.1 | ||

| ALD_D003882 | 12 | 20 | 1.60 | 0.131 | ||

| AUS_D000668 | 12 | 20 | 1.60 | 0.131 | ||

| ALD_D003907 | 12 | 20 | 3.00 | 0.235 | ||

| AUS_D000667 | 12 | 20 | 3.00 | 0.235 | ||

| ALD_D003096 | 12 | 25 | 1.20 | 0.116 | ||

| ALD_D003098 | 12 | 25 | 3.00 | 0.275 | ||

| TP-954 | 12 | 30 | 2.50 | 0.267 | ||

| ALD_D000541 | 12 | 40 | 3.00 | 0.397 | ||

| CAM_A001268 | 12.7 | 19.05 | 3.18 | 0.245 | ||

| CAM_D004737 | 12.7 | 25.4 | 1.57 | 0.155 | ||

| CAM_A001029 | 12.7 | 25.4 | 3.18 | 0.299 | ||

| CAM_A000027 | 15 | 20 | 1.50 | 0.136 | ||

| CAM_A000186 | 15 | 20 | 2.00 | 0.178 | ||

| TP-441 | 15 | 20 | 2.00 | 0.178 | ||

| TP-200 | 15 | 25 | 2.00 | 0.205 | ||

| CAM_A000187 | 15 | 25 | 2.00 | 0.205 | ||

| CAM_A000656 | 15 | 25 | 3.00 | 0.3 | ||

| TP-878 | 15 | 30 | 1.50 | 0.50 | 0.18 |

Related Category

Wire Mesh

Pipe Fittings

Building Glass

Aluminum Profile

Plywood

Window

Ceiling

Mirror

Aluminum Composite Panel

Wallpaper

Fireplace, Stove & Parts

Composite Pipe & Tube

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.